Addressing Climate Change (Information Disclosure Based on the TCFD Recommendations)

MITSUI E&S Group recognizes that climate change is an important sustainability issue that needs to be solved. One of the characteristics of our core business is that the greenhouse gas (GHG) emissions from the operation of our products are higher than the GHG emissions from the manufacturing of our products. In light of this reality, we identify the issue of climate change as one of our material issues, and endeavor to contribute to the realization of a decarbonized society by including climate change in our business issues and focusing on the development of products to help reduce CO2 emissions.

Strategy

We conducted a scenario analysis of risks and opportunities related to climate change, set material issues directly related to the business and management foundations of the MITSUI E&S Group, and incorporated those issues into our business strategy.

| The 2°C scenario | The 4°C scenario | |

|---|---|---|

| Analysis Results | - Risks: Increased manufacturing costs due to the introduction of carbon taxes and CO2 emission regulations. - Opportunities: Expansion in demand for non- fossil fuel products driven by the promotion of low-carbon initiatives. |

- Risks: Intensification of extreme weather events due to the lack of promotion of policies such as CO2 emission regulations. - Opportunities: Our company becoming an alternative supplier to avoid or quickly recover from damage caused by extreme weather events. |

| Impact | The increase in profits from opportunities outweighs the increase in risks. | The physical risk impact on production sites is significant. |

| Recommended Actions | - Develop and market products that use non-fossil fuels. - Reduce the use of fossil fuels and electricity in factories, and cut CO2 emissions by using green power. |

- Construct seawalls to prevent damage from typhoons and storm surges. |

2°C Scenario Analysis Results

Setting the Materiality issue "Creating of a Decarbonized Society" and Incorporating it into Business Strategy

| Material issues | Initiatives |

|---|---|

| Creating a decarbonized society | - Development and Sale of Marine Engines: Focus on engines that use green fuels such as LNG, methanol, ammonia, and hydrogen. - Development and Sale of Zero-Emission Transtainers®: Utilize hydrogen fuel cells to create zero- emission transport solutions. |

| - CO2 Reduction in Group Companies' Production Activities: Implement measures to reduce CO2 emissions across the production activities of group companies. |

| Marine Engines CO2 reduction rate by fuel type* | - Methanol/LNG: 5% to 24% reduction - Ammonia/Hydrogen: 95% reduction |

*Compared to heavy oil

Indicators and targets

Material issues: Creating a decarbonized society

Target 01

Through cumulative sales and operation units from 2022 to 2030 of environmentally friendly products onto the market CO2 reductions:

-10 million t-CO2/year or more.

Target 02

CO2 emissions reductions from production activities through expansion of green power :

-10 thousand t-CO2/year or more.

Through cumulative sales and operation units of environmentally friendly products onto the market CO2 reductions

Current Progress

In pursuit of our goals, we are advancing the development of new fuel engines and enhancing our production systems for marine engines. Additionally, we have developed and launched world's first hydrogen fuel cell zero emission port cranes.

(1) Enhancement of production facilities for new fuels

- Expansion of dual-fuel engine test stands

- Expansion of LNG fuel supply facilities

- Establishment of hydrogen and ammonia supply facilities

(2) Commercial operation of the world's first hydrogen fuel cell zero emission Transtainer®.

- We, along with our U.S. subsidiary PACECO®, have commenced the commercial operation of the world's first hydrogen fuel cell zero emission Transtainer® at the Port of Los Angeles.

- The Ports of Los Angeles and Long Beach in California have set a Clean Air Action Plan to achieve zero emissions for all cargo handling equipment by 2030. Our company will contribute by supplying zero-emission cranes.

Governance

We position SDGs risks, including climate change, as one of our business risks and strive to prevent these risks from materializing. The "Internal Control Committee," chaired by the executive officer in charge of the Corporate Planning Department, monitors management-related risks, including issues related to climate change. If there are significant matters, they are reported to the Board of Directors for discussion.

Governance structure

Risk Management

The Internal Control Committee mentioned above follows the steps below to follow up on our group's efforts regarding materiality.

Short- and mid-term

| Matters to follow up on | Follow up method | |

|---|---|---|

|

1) Grasp of actual condition (annual CO2 emissions reduction survey) |

Progress in the development of low-carbon products | Comparison with the development scherudle for the period of mid- and long-term plan |

| Reduction of the CO2 emissions of the MITSUI E&S Group’s products | Confirmed with data calculated from production horsepower, number of products sold, and fuel efficiency at the time of measurement during internal factory trial operation | |

| Reduction of the CO2 emissions of the production activities of the companies of the MITSUI E&S Group | Check annual energy consumption | |

| 2) Evaluation | Evaluate any deviation from fiscal year targets | |

| 3) Management | If any deficiencies are identified, notify the our operating divisions, our corporate divisions (Corporate Planning Dept. or HR & General Affairs Dept.) and the operating companies to formulate an improvement plan. | |

Long term

| 1) Conduct scenario reanalyses |

|---|

| 2) Check if material issues need to be revised |

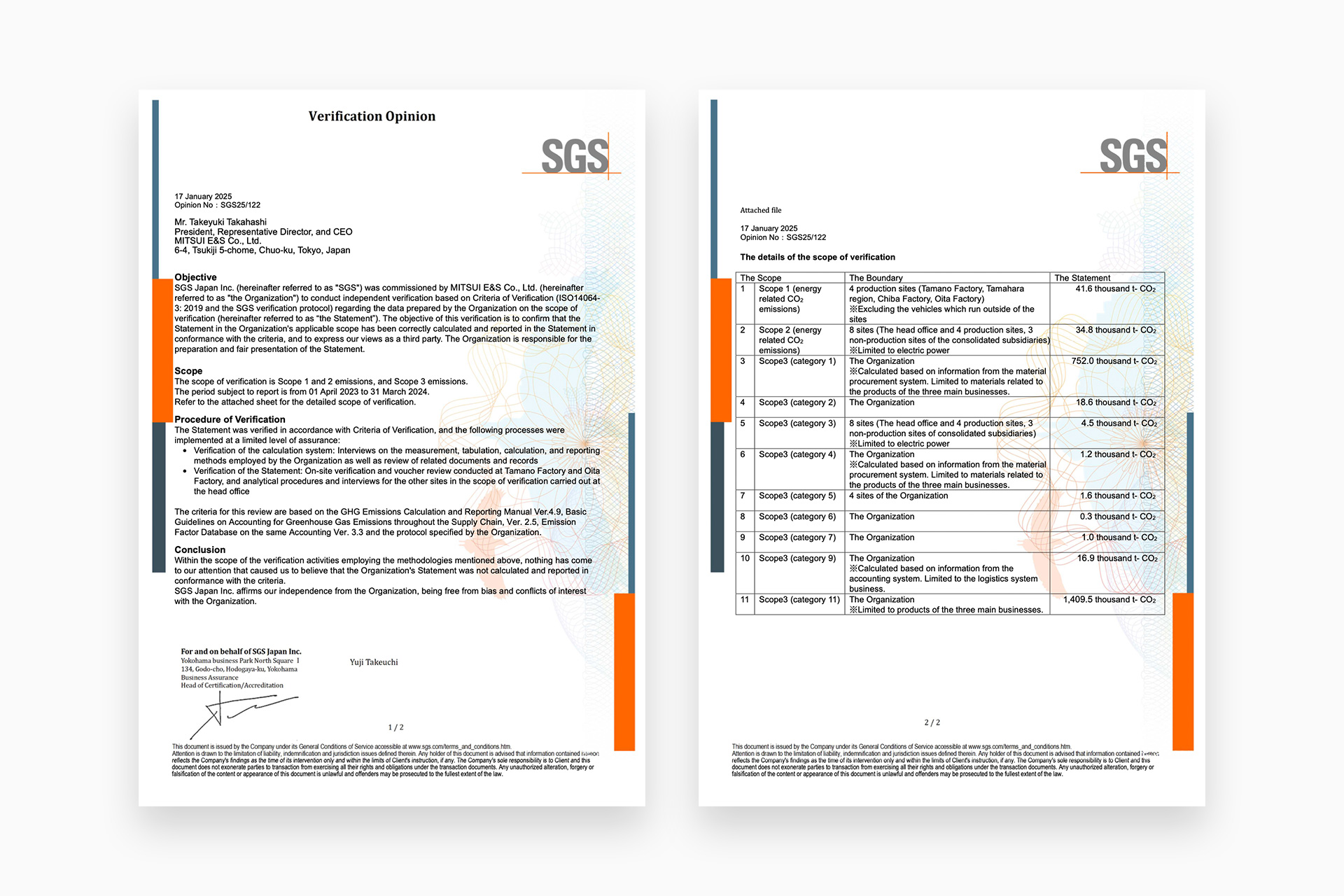

Scope 3 emission and third-party verification

As a step towards creating the materiality issues set by our group, we have started calculating our Scope 3 emissions from the actual results of FY 2023.

To ensure the accuracy of these efforts, we have annual verifications from SGS Japan Inc. as external third-party organizations for our GHG emissions since FY 2023.

We have expanded the calculating coverage for FY 2024 in comparison with fiscal 2023, based on comments and discussions with SGS Japan Inc.

CO2 emissions of our verified coverage for FY2024

| Scope | Emission Categories | FY2023 Emission ( kt-CO2) |

FY2024 Emission ( kt-CO2) |

FY2024 Emission (Estimated value based on the coverage of FY2023) |

|---|---|---|---|---|

| Scope1 | Direct Emissions: From fuel consumption within the company (*1) | 41,6 | 43.7 | (41.3) |

| Scope2 | Indirect Emissions: From electricity consumption within the company (*1 *2) | 34,8 | 39.7 | (33.6) |

| Scope3 |

1.Emissions from the procured goods (*3) |

752,0 |

831.8 |

(768.1) |

|

2.Emissions from the introduction of capital goods |

18.6 |

26.8 |

|

|

|

3.Emissions from the production of fuel and energy (*1 *2 *4) |

4.5 |

12.5 |

(4.5) |

|

|

4.Emissions from upstream transportation and distribution(*5) |

1.2 |

18.9 |

(1.3) |

|

|

5.Emissions from waste treatment from business activities |

1.6 |

2.4 |

|

|

|

6.Emissions from employee business travel |

0.3 |

0.3 |

|

|

|

7.Emissions from employee commuting |

1.0 |

1.0 |

|

|

|

9.Emissions from downstream transportation and distribution(*6) |

16.9 |

0.0 |

(17.6) |

|

|

11.Emissions from the use of sold products |

1,409.5 |

1,650.4 |

Remark: The verified coverage for FY2024 and changes from the previous year

Third-party certification for GHG emissions