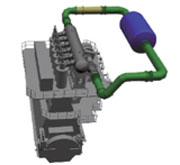

■ iSCR (Integrated high-pressure SCR)

Developed by WinGD, the iSCR (Integrated High-Pressure Selective Catalytic Reduction) system is an engine-integrated high-pressure SCR solution designed to comply with IMO NOx emission regulations.

Unlike conventional SCR systems that require significant onboard space, the iSCR is compactly installed beneath the engine’s exhaust receiver. This innovative layout greatly reduces the required engine room space, offering increased flexibility in piping design and significantly improving outfitting efficiency at shipyards.

In addition, the iSCR achieves a substantial reduction in catalyst volume compared to conventional systems, contributing to lower operating costs. Despite these enhancements, the NOx reduction performance remains on par with traditional SCR systems.

With its space-saving design, cost efficiency, and regulatory compliance, the iSCR offers a next-generation NOx reduction solution that delivers significant benefits across all phases of ship design, construction, and operation.

|

|

|

||

| Conventional HP-SCR | iSCR (Integrated HP-SCR) |

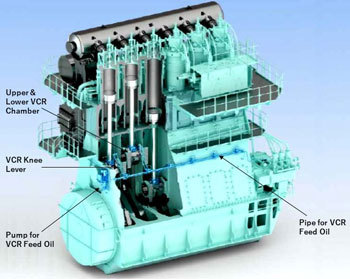

■ VCR(Variable Compression Ratio)System

The Variable Compression Ratio (VCR) system automatically adjusts the compression ratio of the cylinder, optimized according to engine output and fuel type, by controlling the piston position. This enables reductions in both fuel consumption and exhaust emissions.

Depending on operational conditions such as vessel load, the system can achieve approximately 3% improvement in fuel efficiency in gas mode and about 6% in diesel mode, contributing significantly to reducing fuel costs and CO₂ emissions during ship operation.

This innovative system was the world's first to be commercialized through a collaboration between Mitsui E&S DU and licensor WinGD, and it plays a vital role in advancing toward a decarbonized maritime industry.

|