- Home

- Business & Products

- Logistics & Systems

- Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive Maintenance

Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive MaintenanceBusiness & Products

-

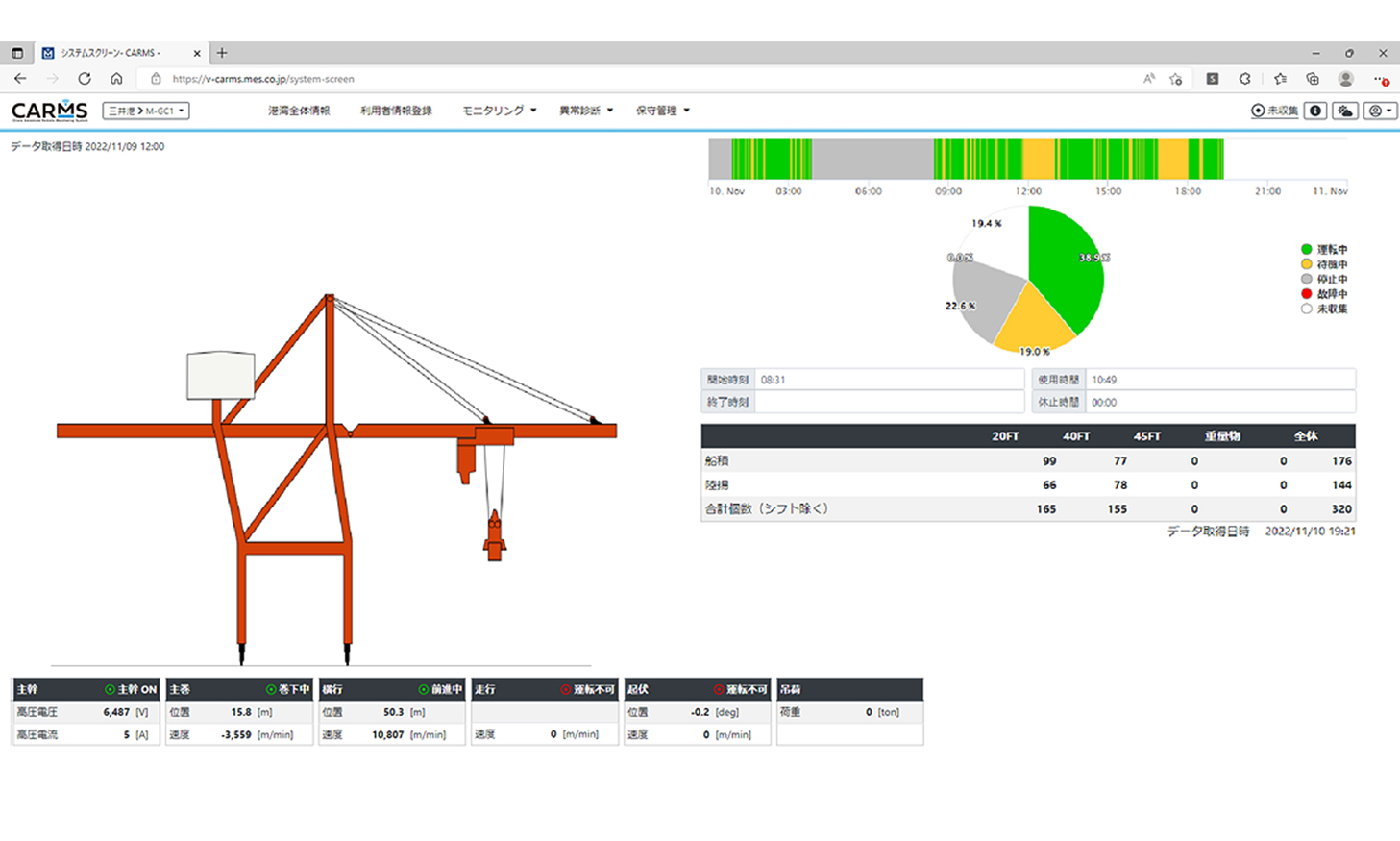

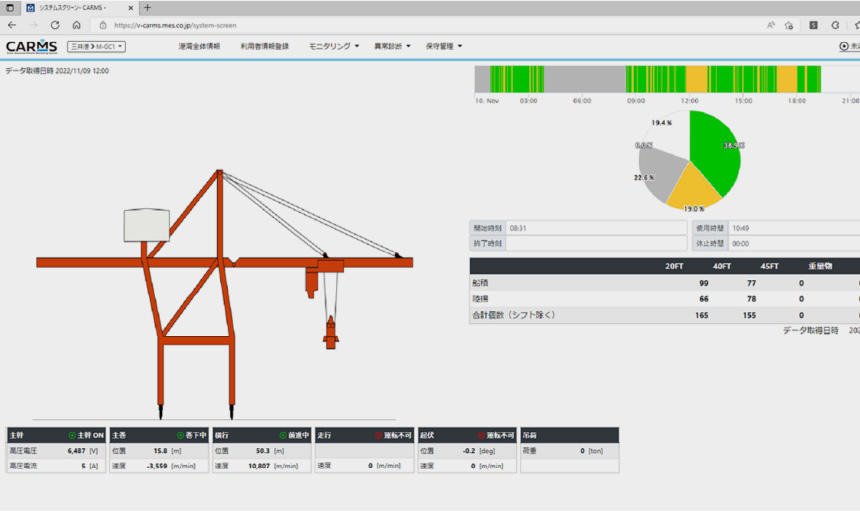

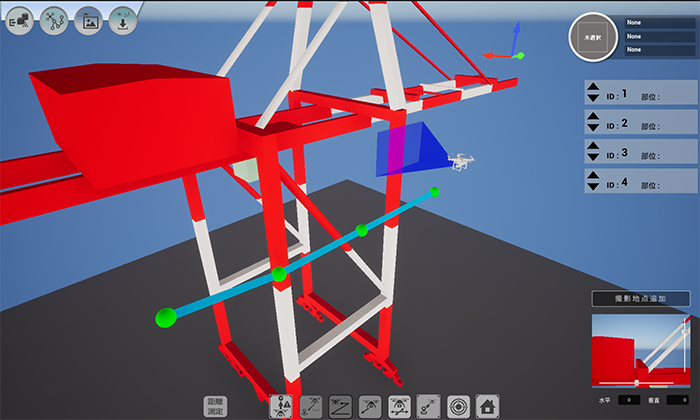

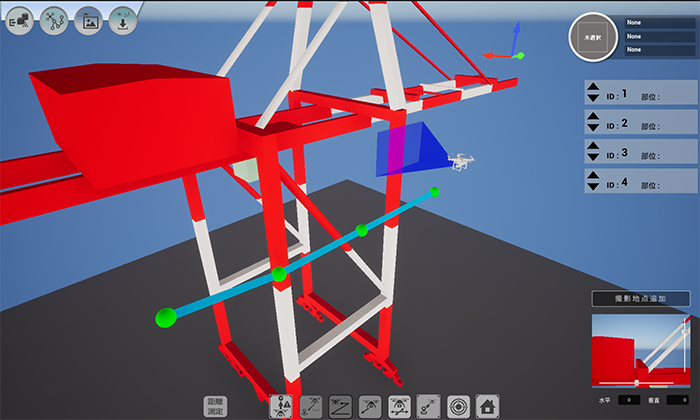

CARMS System Screen

- Realization of IoT platform for next-generation crane maintenance management

- CARMS collects and analyzes all data related to cranes. These data are transferred and accumulated on the cloud managed by our company. In addition, data can be visualized and viewed through a web browser on a PC or tablet. This makes it possible to monitor the crane status "anytime" and "anywhere". Furthermore, by adding sensors to various equipment on the crane, we are constantly expanding advanced preventive maintenance functions that make it possible to grasp equipment lifespans and signs of failure. Through CARMS, we will contributing to the improvement of the reliability of customer ports and streamlining port operations.

※CARMS is the shortform of the Crane Advanced Remote Monitoring System provided by our company.

Main Features

- Store crane data in the cloud

- The status of the crane can be checked from the office or even outside

- Even if the data collection equipment breaks down, the data accumulated so far will be maintained

- If you don't want to use the cloud, you can also provide it as a stand-alone

- Check data with a web browser

- Can be monitored on a normal PC. No special device or software required.

- Multiple users can share information based on the same screen

- Download reports and data from remote locations

- Output work diaries, cargo handling reports, wind direction and speed logs, etc.

- No need to climb the crane to obtain the output data

- Analyzing log data and sensor data for preventive maintenance

- Detect signs of failure before it breaks

- Grasping the remaining service life of parts

- As it is an option, functions can be selected according to users necessary.

It is also possible to develop functions according to the customer's problems.

Delivery Records

[Ports Introduced with CARMS]

Introduced to 6 ports in Japan

(Hachinohe, Shinagawa, Oi, Sakaiminato, Takamatsu, Shibushi)

[Preventive maintenance function]

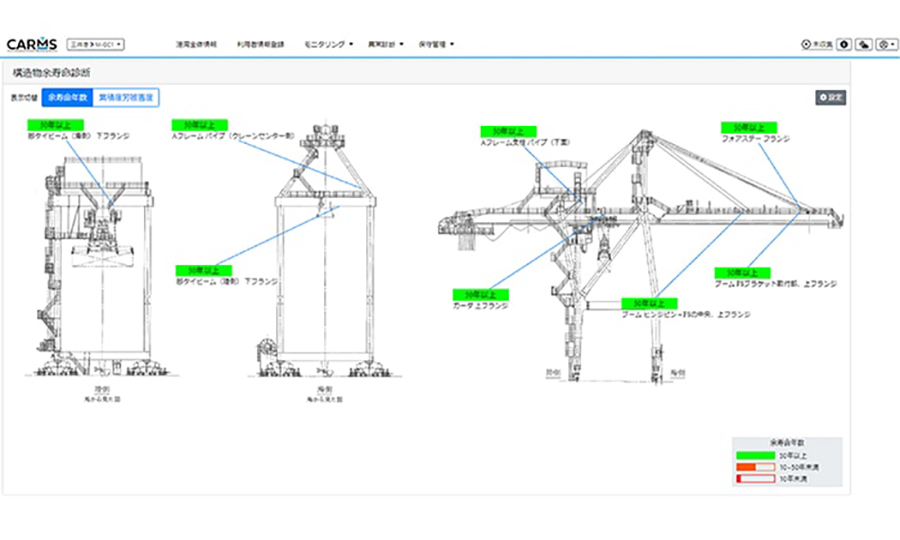

● Structure life diagnosis

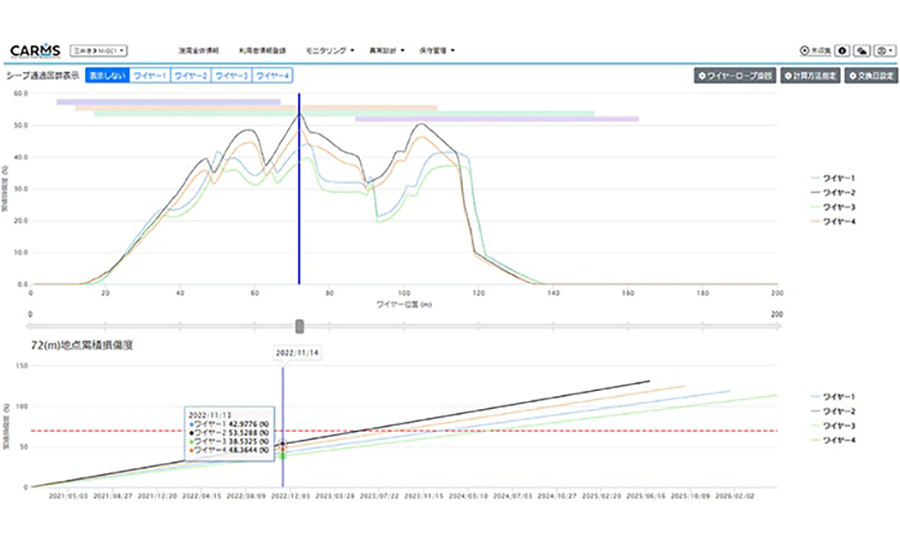

● Wire rope life diagnosis

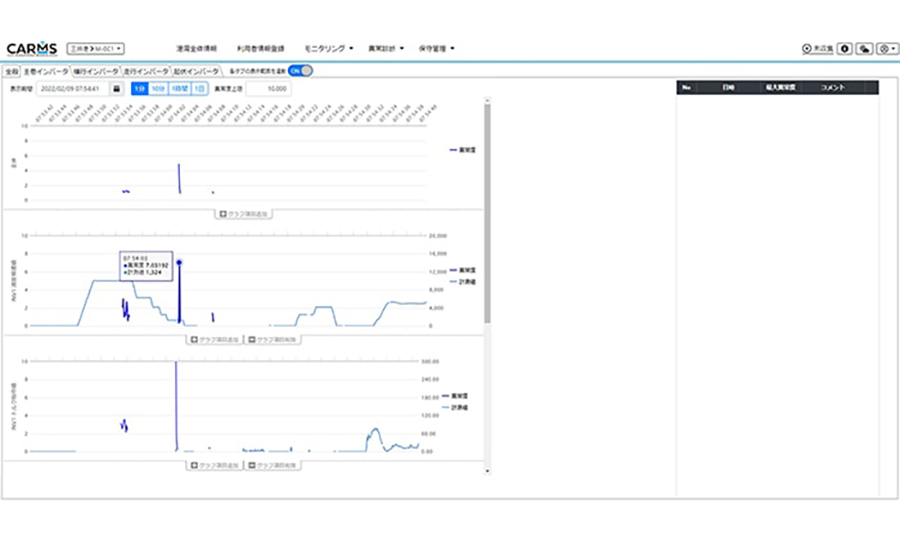

● Inverter abnormality detection

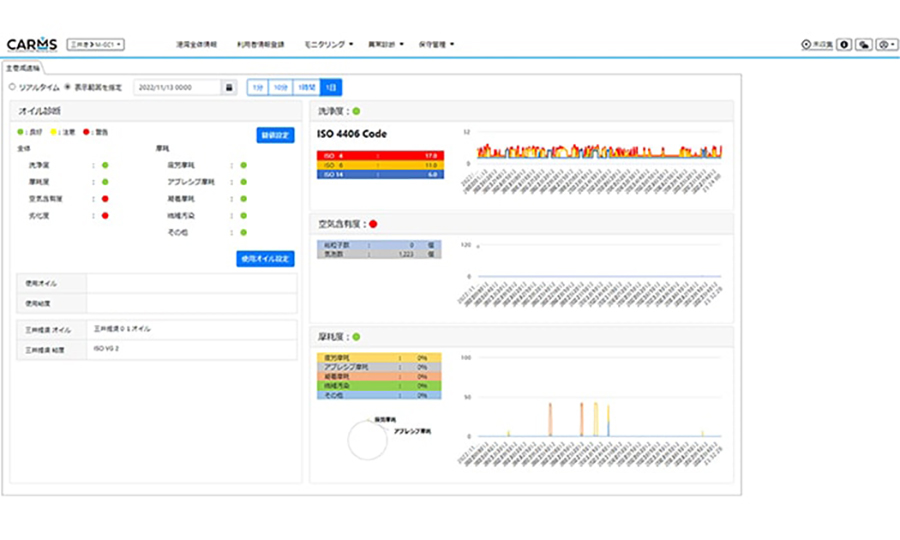

● Diagnosis of reducer oil

● Detecting abnormalities in reducer due to vibration...

Others under active development

-

Inverter Abnormality Diagnosis

-

Decelerator Oil Diagnosis

-

Structure Remaining Life Diagnosis

-

Wire Rope Remaining Life Diagnosis

-

Decelerator Failure Detection due to Vibration

Inquiries about products

- Contact

- MITSUI E&S Co., Ltd.

Logistics System Division

Techno Service Center

- TEL

- +81-863-23-2393

- FAX

- +81-863-23-2443

Inquiries about after-sales service

- Contact

- MITSUI E&S Co., Ltd.

Logistics System Division

Techno Service Center

- TEL

- +81-863-23-2393

- FAX

- +81-863-23-2443

Catalog

- New Business Development

- Decarbonization business

- Industrial Machinery

- Mechatronics & Special Construction

- After-sales Services

- Marine Propulsion System

- Logistics & Systems

- Portainer®(Quayside Container Crane)

- Transtainer®(Transfer Crane in Container Yard)

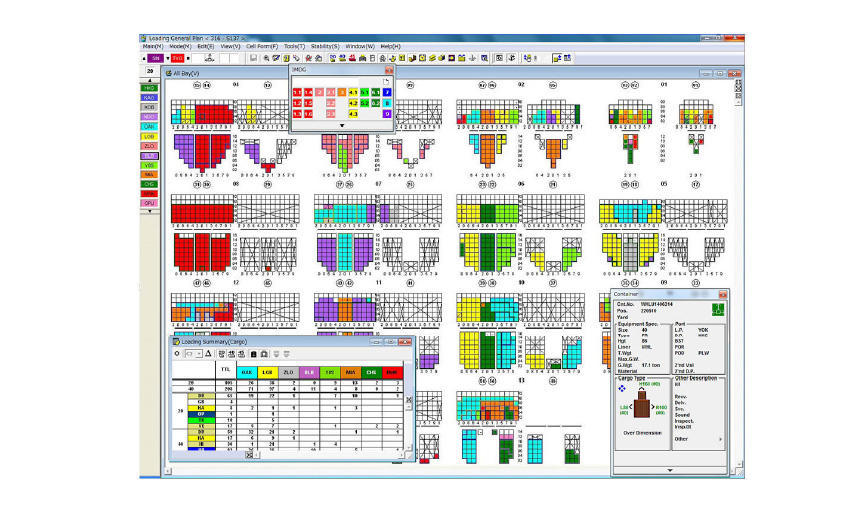

- CTMS

- Crane Inspection by DroneSnap(Automatic Flying Drone)

- Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive Maintenance

- Drone Snap: flight file creation application for equipment inspection/patrol

-

-

- Portainer® (Quayside Container Crane)

-

-

-

- Transtainer® (Transfer Crane in Container Yard)

-

-

-

- Container Terminal Management System (CTMS)

-

-

-

- Crane Inspection by DroneSnap(Automatic Flying Drone)

-

-

-

- Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive Maintenance

-

-

-

- Drone Snap: flight file creation application for equipment inspection/patrol

-

-

-

- (Copy) Drone Snap: flight file creation application for equipment inspection/patrol

-