- Home

- Business & Products

- Ground-Penetrating Radar

- Tunnel Inspection

Tunnel InspectionBusiness & Products

-

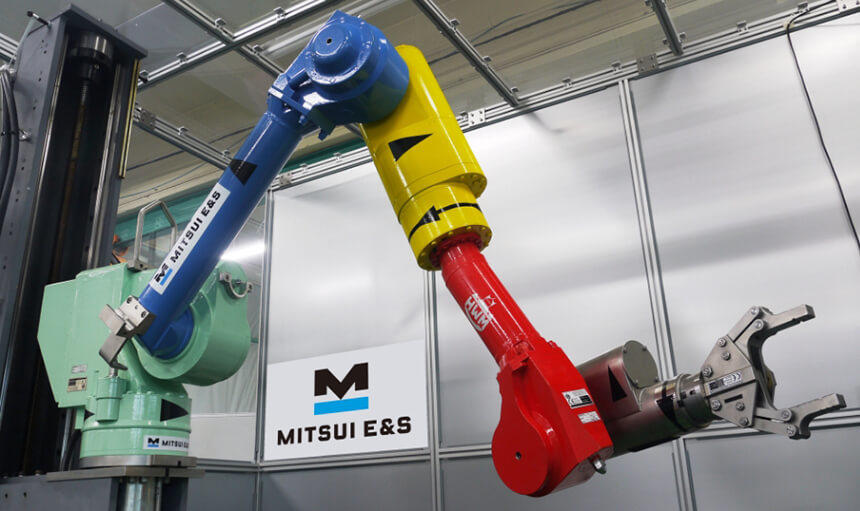

Tunnel lining surface picture system TC3 detecting 0.2mm wide crack (NETIS No. : KT-190037-A / Name : Tunnel lining surface picture system)

-

Tunnel inspection car with Multi-Path Linear Array RADAR

- We can provide non-destructive inspection for tunnel lining surface and inner part as well.

- Tunnel lining surface picture system TC3 has line sensor cameras and LED lights. It can detect 0.2mm wide crack under maximum 80km/hr drive. It has passed the evaluation examination of "Road tunnel inspection and record support robot technique" by Ministry of Land, Infrastructure, Transport and Tourism. It is possible to use TC3 for official periodic road tunnel inspection.

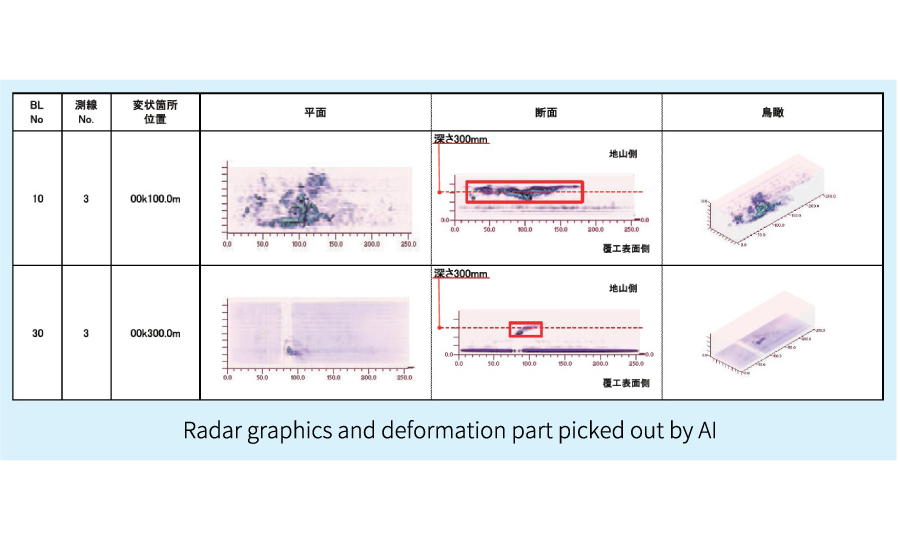

Tunnel inspection car is equipped with our original Multi-Path Linear Array RADAR, and it can inspect the inner part of tunnel. The radar type is exchangeable, and it is possible to inspect dorsal hollow as well. It is possible to get 3D data through Multi-Path Linear Array RADAR. We can provide nearly actual replicated 3D graphics of the deformed part, which made it possible to grasp the inside condition of tunnel lining surface intuitively.

This technique has been applied and utilized for railway tunnel concrete lining inspection car developed together with East Japan Railway Company as well.

It is possible to make a development diagram conflating the surface picture data by TC3 and inner deformation data by tunnel inspection car. We can provide useful data for detecting the part needing emergency repair by such development diagram conflating surface and inner condition data.

Main Features / Delivery Record

-

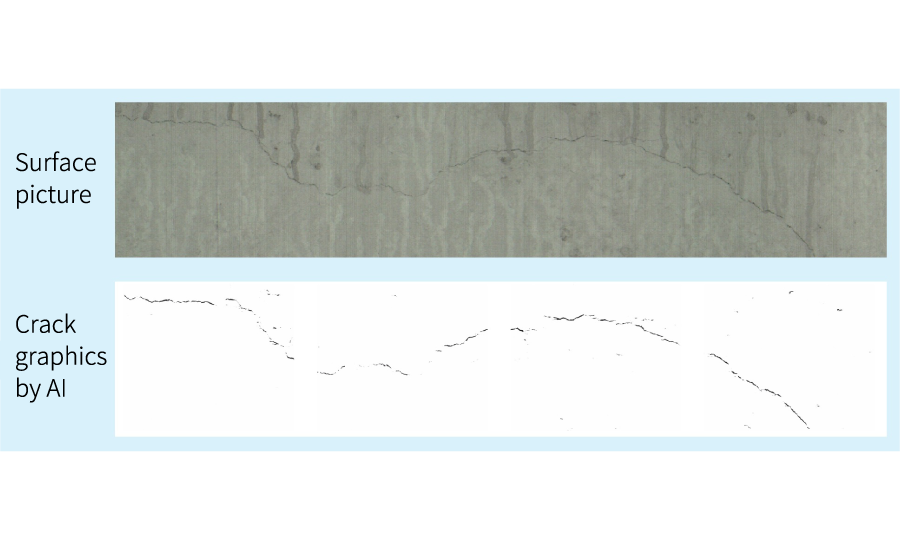

Tunnel Crack Graphics by AI

We developed AI technique to draw crack graphics from tunnel surface picture together with Nomura Research Institute, Ltd. Traditionally tunnel inspection was carried out by visual inspection. This AI technique made it possible to draw crack graphics and to detect the crack automatically, which realized efficient and accurate analysis method and made it in a short time. -

Tunnel Radar Graphics and Deformation part picked out by AI

We can pick out accurately deformation part by AI auto analysis from 3D analysis graphics through Multi-Path Linear Array RADAR. This technique made it possible to provide analysis data without personal difference immediately.

Inquiries about products & after-sales service

- Contact

- Mitsui E&S Technical Research Co., Ltd.

- TEL

- +81-863-23-3029

- FAX

- +81-863-23-3030

- New Business Development

- Decarbonization business

- Industrial Machinery

- Mechatronics & Special Construction

- After-sales Services

- Marine Propulsion System

- Logistics & Systems

- Portainer®(Quayside Container Crane)

- Transtainer®(Transfer Crane in Container Yard)

- CTMS

- Crane Inspection by DroneSnap(Automatic Flying Drone)

- Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive Maintenance

- Drone Snap: flight file creation application for equipment inspection/patrol