Drone Snap: flight file creation application for equipment inspection/patrol

Drone Snap makes it easy to create flight files for your drone to fly automatically, and Drone Snap Cloud also allows you to efficiently manage captured images.

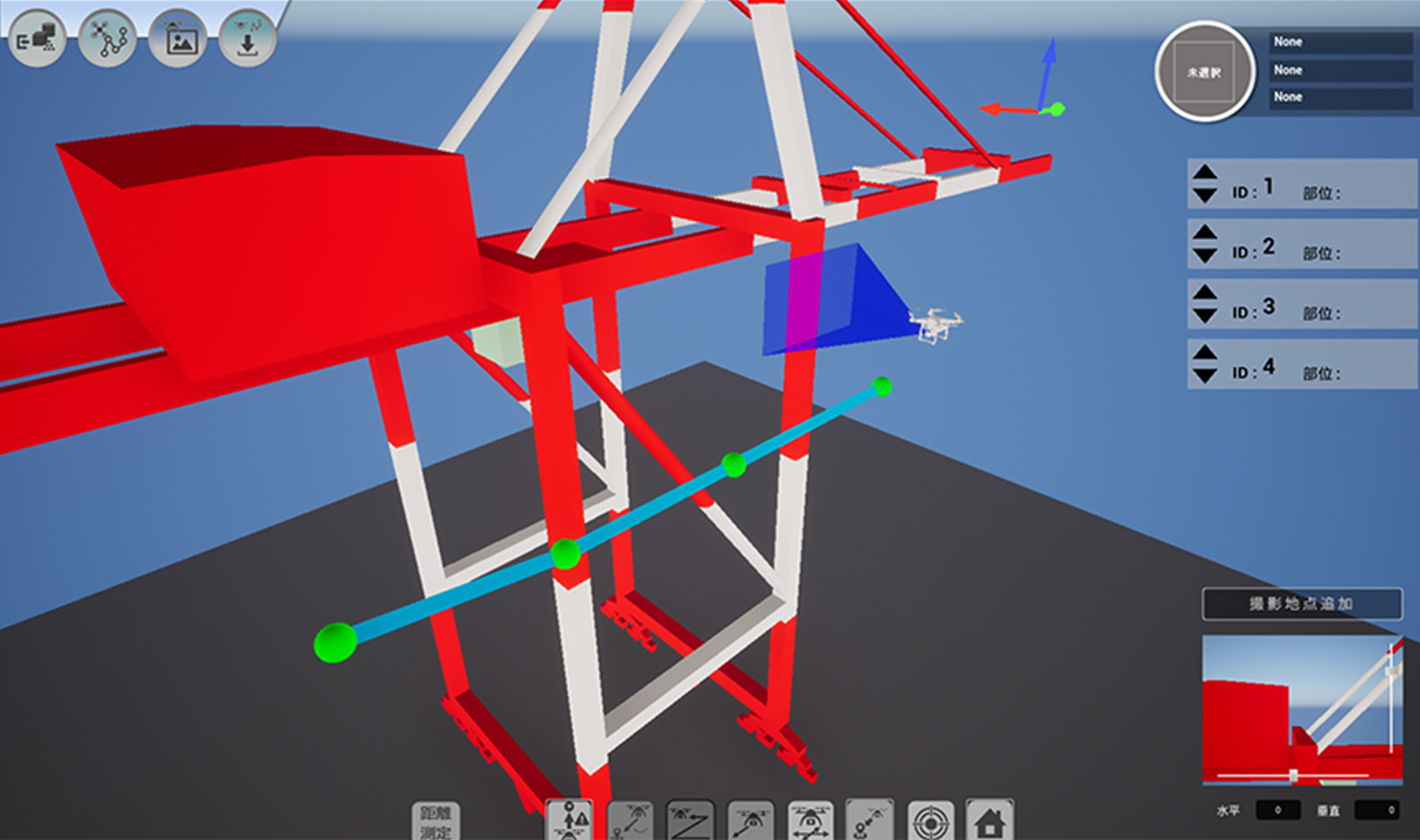

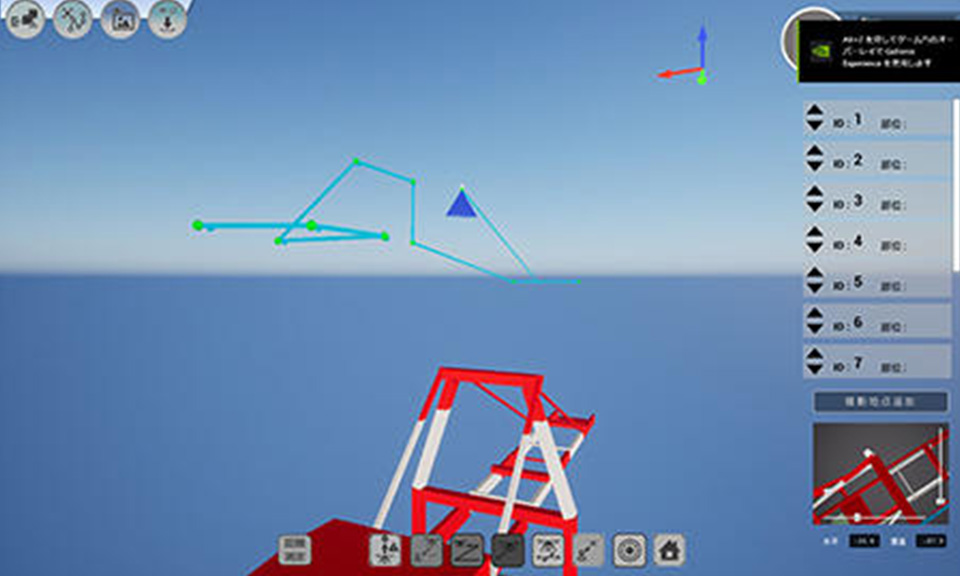

"Drone Snap" is an application developed by MITSUI E&S. You can load 3D models or point cloud data of the equipment to be inspected into the application to create automatic flight routes for drones. Drone Snap can be used for all kinds of large equipment and is compatible with a wide range of drones.

"Drone Snap Cloud" is a cloud-based service that allows you to manage images taken by drone. It can be used together with Drone Snap, automatically sort captured images, and compare them in chronological order. Drone Snap has a function to detect rust by AI.

Main Features

- You can easily create automatic flight routes for drones.

- Regardless of the skill of the drone operator, anyone can acquire the same highly accurate images of inspection points.

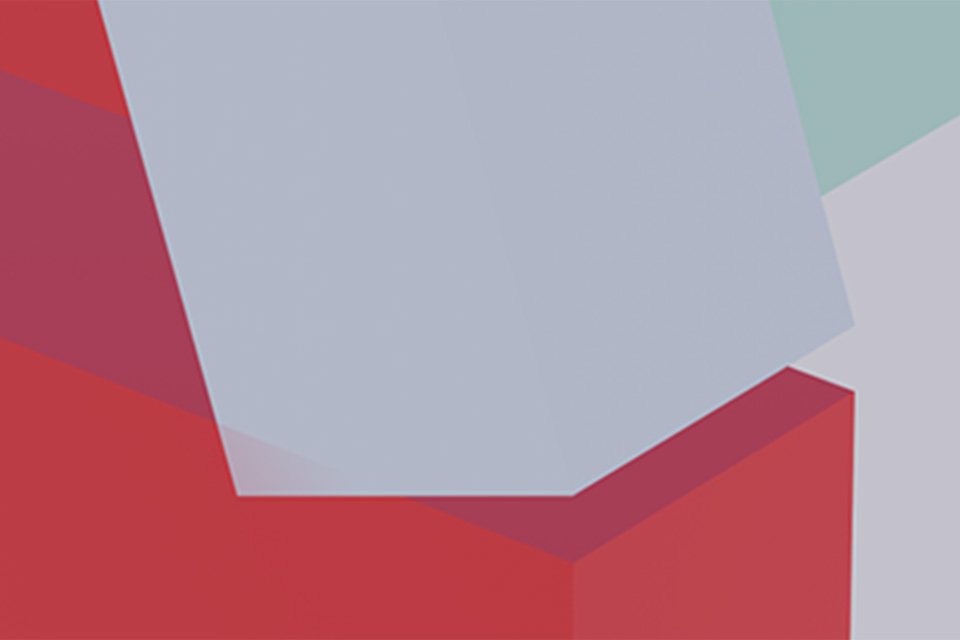

- Using a 3D-CAD model, you can set the shooting position and camera angle of the drone to take pictures of the inspection points, so you can check in advance what kind of images can be taken.

- Since all drones fly and shoot automatically, inspections can be carried out efficiently and safely.

- It can be carried out more efficiently than conventional drone inspection by manual operation by humans. (it can be done in 0.5 days instead of 3 days by manual operation).

- There are no shooting omissions (inspection omissions).

- Compared to conventional visual inspection by humans, inspection time can be shortened (it can be done in 0.5 days instead of 1.5 days by humans).

Drone Snap Case Study (Representative Case)

Visual Inspection of Gantry Crane Structure

- Major Improvement of Eggiciency and Photography Time Reduction -

Cranes are required by law to be inspected monthly and yearly. Inspection items include structural inspections, which are performed by human eyes to check for cracks, rust, and corrosion. Under such circumstances, due to the decline in the working population, there is a shortage of engineers who perform actual work, and the transfer of technology from skilled engineers to inexperienced engineers is also an issue.

Since cranes are complex and large-scale structures, scaffolding and heavy machinery are required during inspections, and the safety of workers is also an issue because the work is done at high altitudes.

Based on our knowledge as a crane manufacturer and the inspection know-how we have cultivated over many years, we have achieved significant cost reductions and efficiency improvements by using Drone Snap to perform automatic flight and automatic photography by drones. In addition, by being able to check the shooting location and the images to be taken in advance, it is possible for even inexperienced engineers to acquire high-precision images adequate for inspections.

Photographing the exterior of the structure with a drone

Advantages

- No heavy machinery or scaffolding is required.

- You can set the flight route and check expected result images in advance.

- Everything is automatic: from flight to shooting.

- Rust is automatically determined by AI(when using Drone Snap Cloud).

- If there is a part you want to check in detail during automatic flight, you can switch the drone to manual flight on the spot and take a picture.

- Thorough photography is possible in a short time without missed shots.

Photography time: approx. 30min

Photos taken: 262

3D flight route creation in progress

Comparison of a simulated image and an actual photograph

Contact

Inquiries about products

Drone Snap Service Desk, Marketing Dept., New Business Development Div.