After-sales Service for Gas Turbine Co-generation System

MITUI E&S provides optimal maintenance services based on our high technical capabilities, which are founded on years of experience in the development of our own gas turbines and the overall maintenance technology of power generation systems.

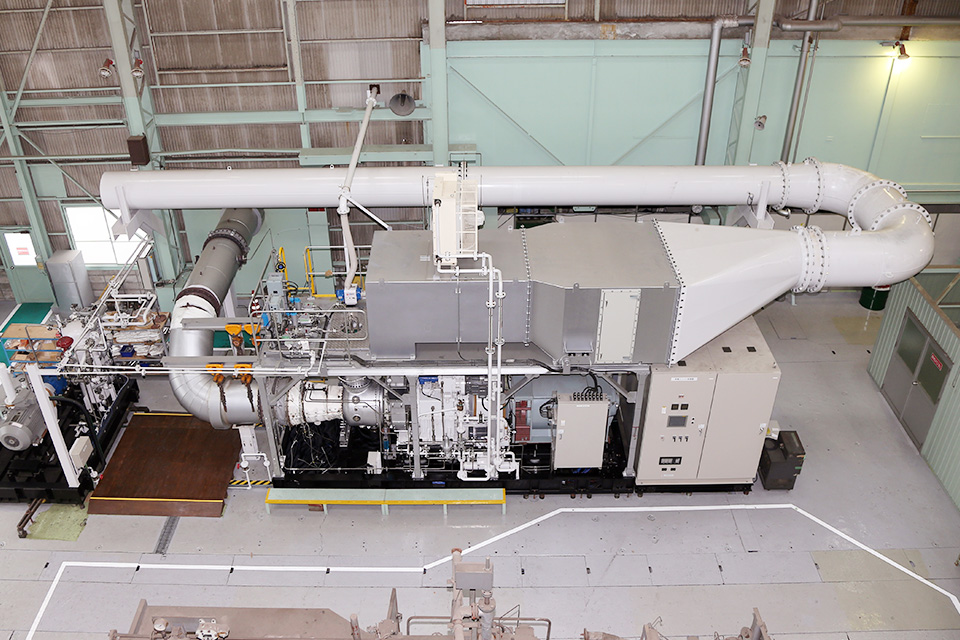

MITSUI E&S gas turbines range from 1 to 24 MW of generating output as gas turbine co-generation units and widely applied such as in food, chemical, semiconductor industries and also district heating and chilling, and have the following features:

Main Features

- High efficiency and low cost

- Simple system configuration

- Environmentally-friendly, a high total efficiency and less NOx & CO2 emissions

- A variety of burning fuels, such as town gas, LPG, kerosene, heavy fuel and byproduct oil

- Application to a variety of purposes, from hospitals, office buildings, etc., to industrial use such as factories.

Lineup of products

MITSUI E&S provides after-sales services to the following our gas turbine co-generation systems.

MSC40 - MSC130

Simple co-generation systems using gas turbines produced by U.S.-based Solar Turbines Inc. in the Mitsui Solar Co-generation (MSC) Series of seven packages ranging from 4MW to 13MW

MACS60 - MACS130

Variable heat and power co-generation systems using gas turbines produced by U.S.-based Solar Turbines Inc. in the Mitsui Advanced Co-Generation System (MACS) Series of five different packages ranging from 7MW to 17MW

SB15 - SB120

Simple cogeneration systems based on the SB15 to SB120 Series of independently developed gas turbines. Four different packages from 3MW to 24MW have been delivered to customers.

GP1000 / MPP1000 / SB5-COPRA / GP1000-RECSS / SB5N

Co-generation systems based on the independently developed SB5 1MW gas turbine. The SB5-COPRA variable heat and power model and the GP1000-RECSS regeneration cycle model have been delivered to customers. The enhanced efficiency SB5N model was recently added to the lineup.

Service

Stable parts and spare engine supply

A complete supply process including design, manufacturing, quality control, procurement system and stock control management has been established to supply necessary parts in a timely manner.

Additionally, gas turbines produced by U.S.-based Solar Turbines Inc. are supported by a system that ensures the rapid supply of spare engines both domestically and internationally in case of emergencies.

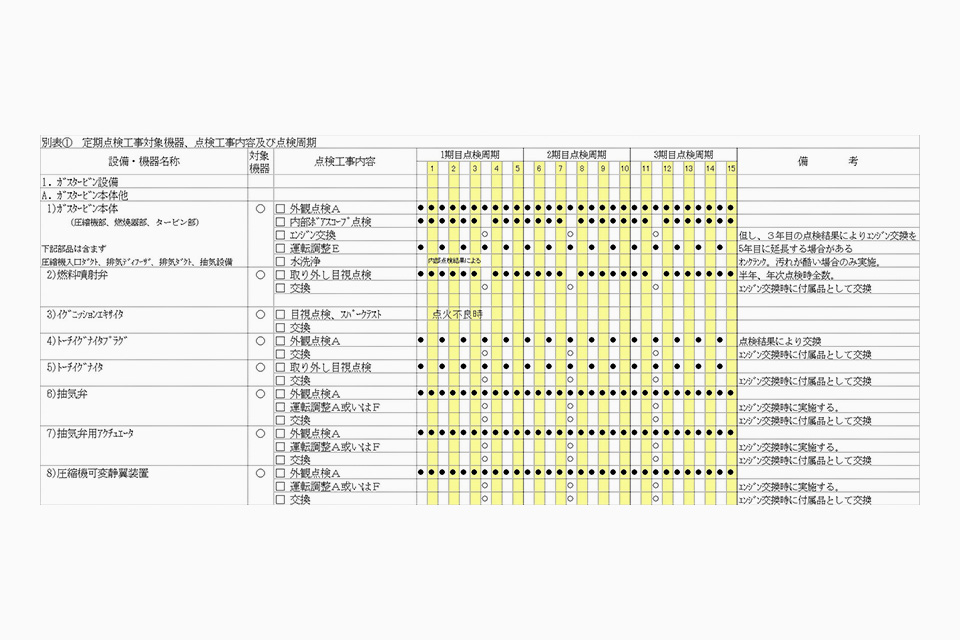

Long-term comprehensive maintenance contract

A budget plan for customers' maintenance cost and facility maintenance management is made easy by leveling out the long-term routine inspection costs as a yearly base.

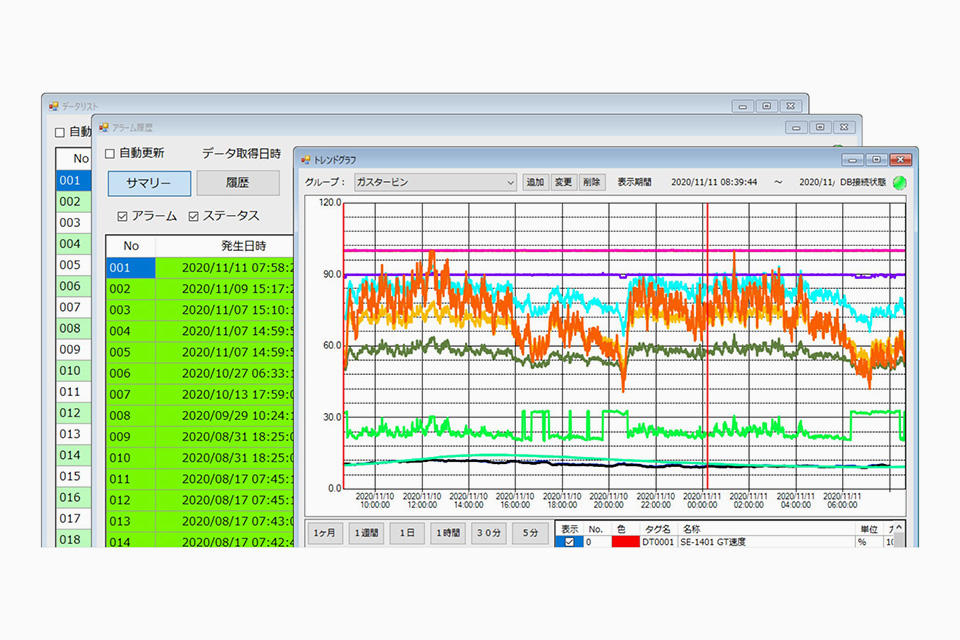

Technical service for emergencies

We respond to customer's expectations with preventive maintenance by tendency management utilizing the complete online support system at Tamano office and emergency response service at abnormal · trouble occurrence. In addition, Tamano and Chibaʼs technical staff at each sales office are developing swift service.

Improvement of facility function and performance

Technical support

Contact

Inquiries about after-sales service

Sales Dept., New Business Development Div. (Tamano)