Logistics & Systems

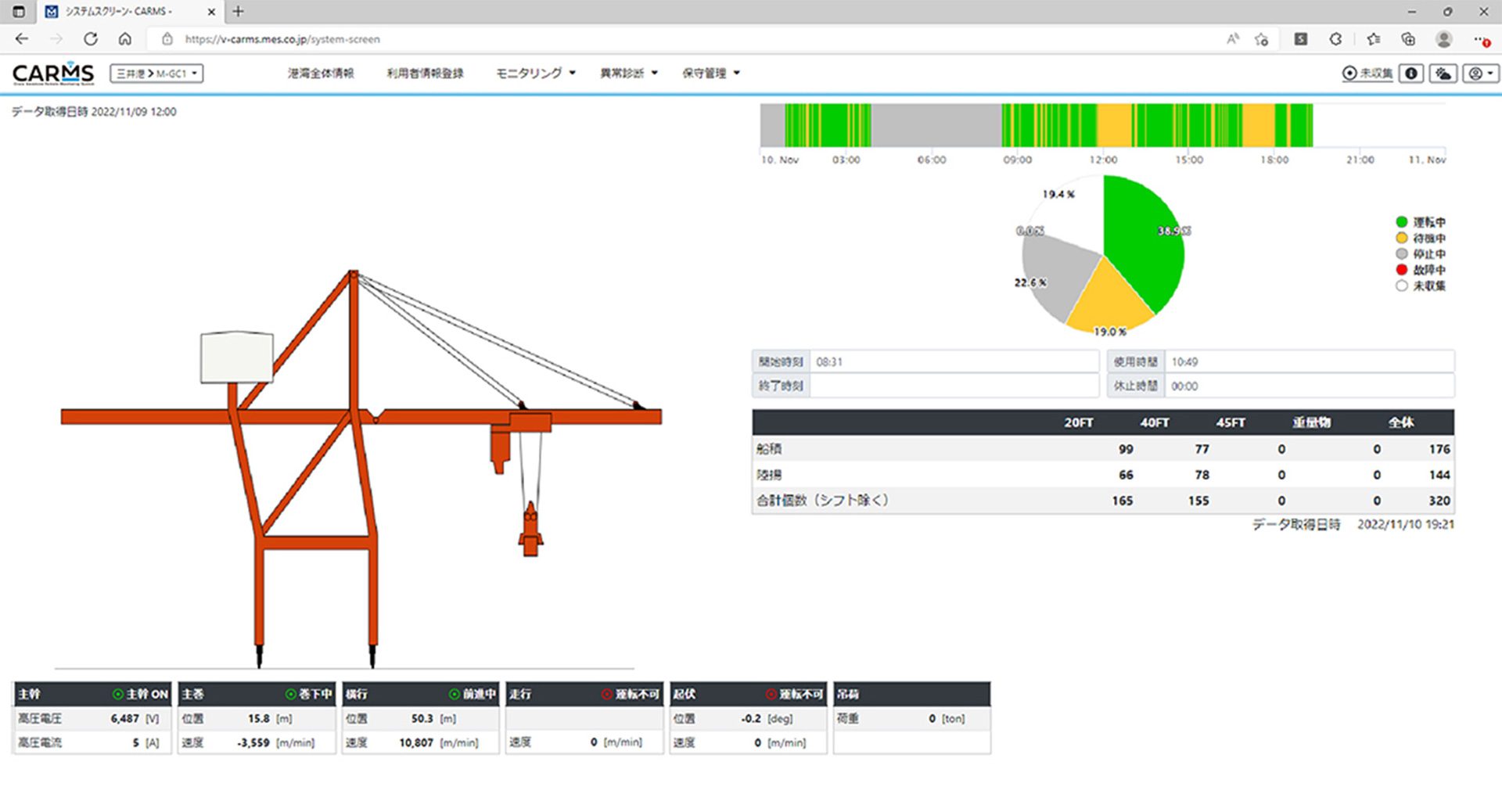

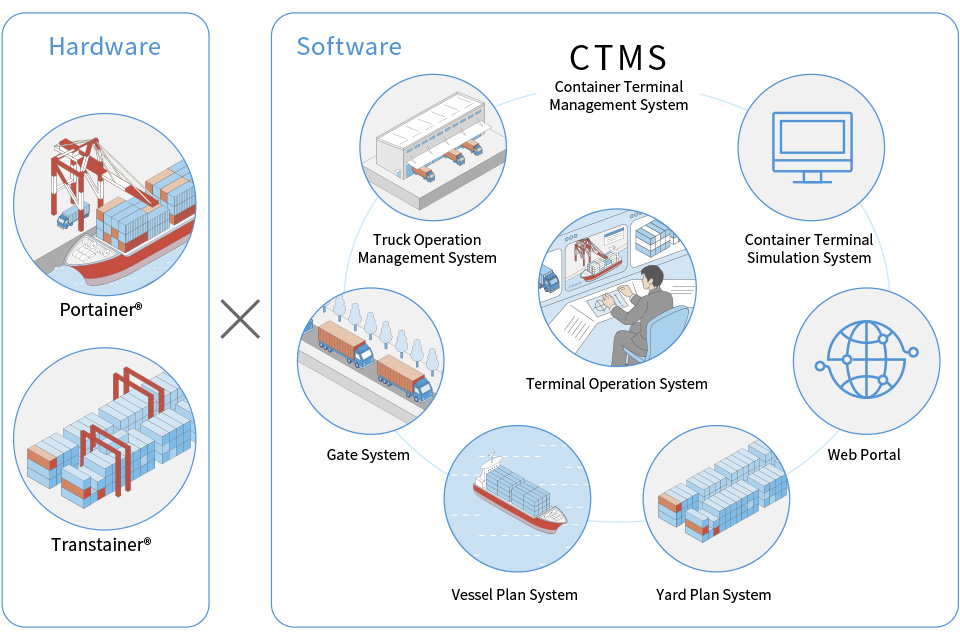

MITSUI E&S holds the top domestic market share for port cranes and supports the entire lifecycle of ports,covering Container Terminal Management System(CTMS), Crane Monitoring Systems, and Advanced Preventive Maintenance by Crane Advance Remote Monitoring System(CARMS). Additionally, we are advancing the development of hydrogen-powered cranes and remote/ automated cranes, contributing to the decarbonization of ports and reducing operational burdens. Furthermore, we are expanding our business into various fields, such as industrial cranes and the application of drone inspection systems to infrastructure facilities.

Cargo Handling Equipment

Since delivering Japan's first Ship-to-Shore crane to Port of Kobe in 1967, we have supplied Ship-to-Shore cranes and Rubber-Tired Gantry cranes to both domestic and international terminals. As a leading manufacturer in Japan, we have accumulated abundant production experiences and expertise not only in container handling cranes but also in industrial cranes, automated cranes, and environmentally friendly cranes.

Delivered Japan's first Ship-to-Shore crane to Port of Kobe

1967

Total Number of Portainer® Supplied

470 units

Total Number of Transtainer® Supplied

1,700 units

PRODUCTS & SERVICES

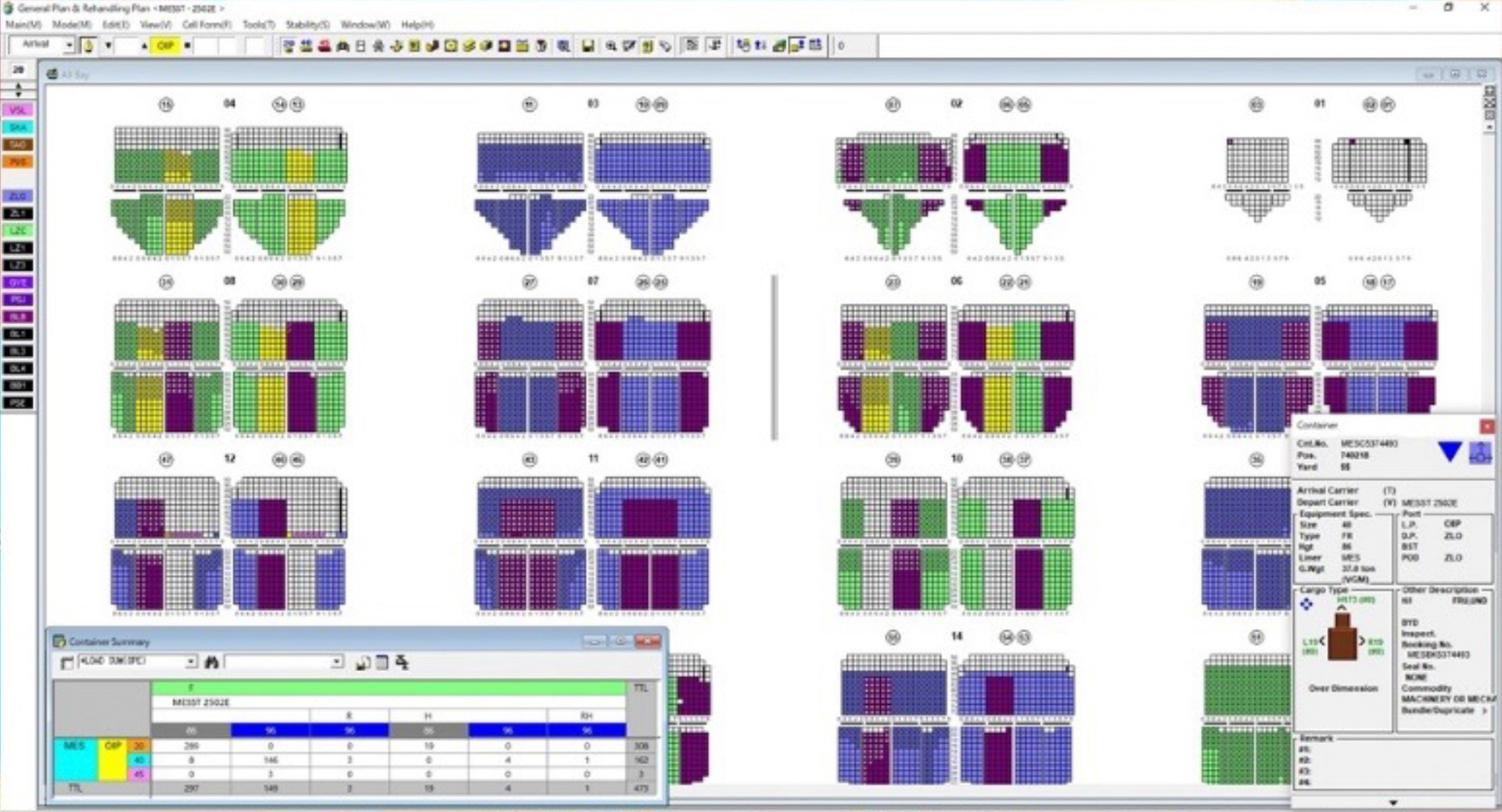

Digital Transformation Services

MITSUI E&S not only provides hardware such as cranes but also develops its own systems to optimize container terminal management, offering comprehensive solutions for container terminals.

PRODUCTS & SERVICES

After-sales Service

By maintaining and improving our superior technology, quality, and after-sales service, we have earned long-term support from our customers. To provide the best quality and service, our group works as one to swiftly carry out on-site repairs, maintenance, and other support.

Cranes Covered

- MITSUI-PACECO® crane

- Portainer® (Ship-to-Shore crane, Quayside Container crane)

- Transtainer® (Rubber-Tired Gantry crane)

-Shipstainer (On-Ship Multi-purpose crane)

- Catenary unloader (Continuous Bulk Cargo Unloader with Bucket) - Various Industrial Cranes

- Unloader Loader

- Level luffing crane

- Goliath crane

- Gantry crane

- Steel mill crane

- Overhead crane

- Jib crane