e-GICS Advance

Engine Monitoring Service

e-GICS Advance is a service that provides condition diagnostics by combining AI anomaly detection, performance and combustion diagnostics based on engine data measured during operation of electronically controlled engines (ME type engine). It has following advantage compared with the conventional "e-GICS":

- Automatic data collection at frequent intervals

- Advanced engine condition diagnosis

Main Features

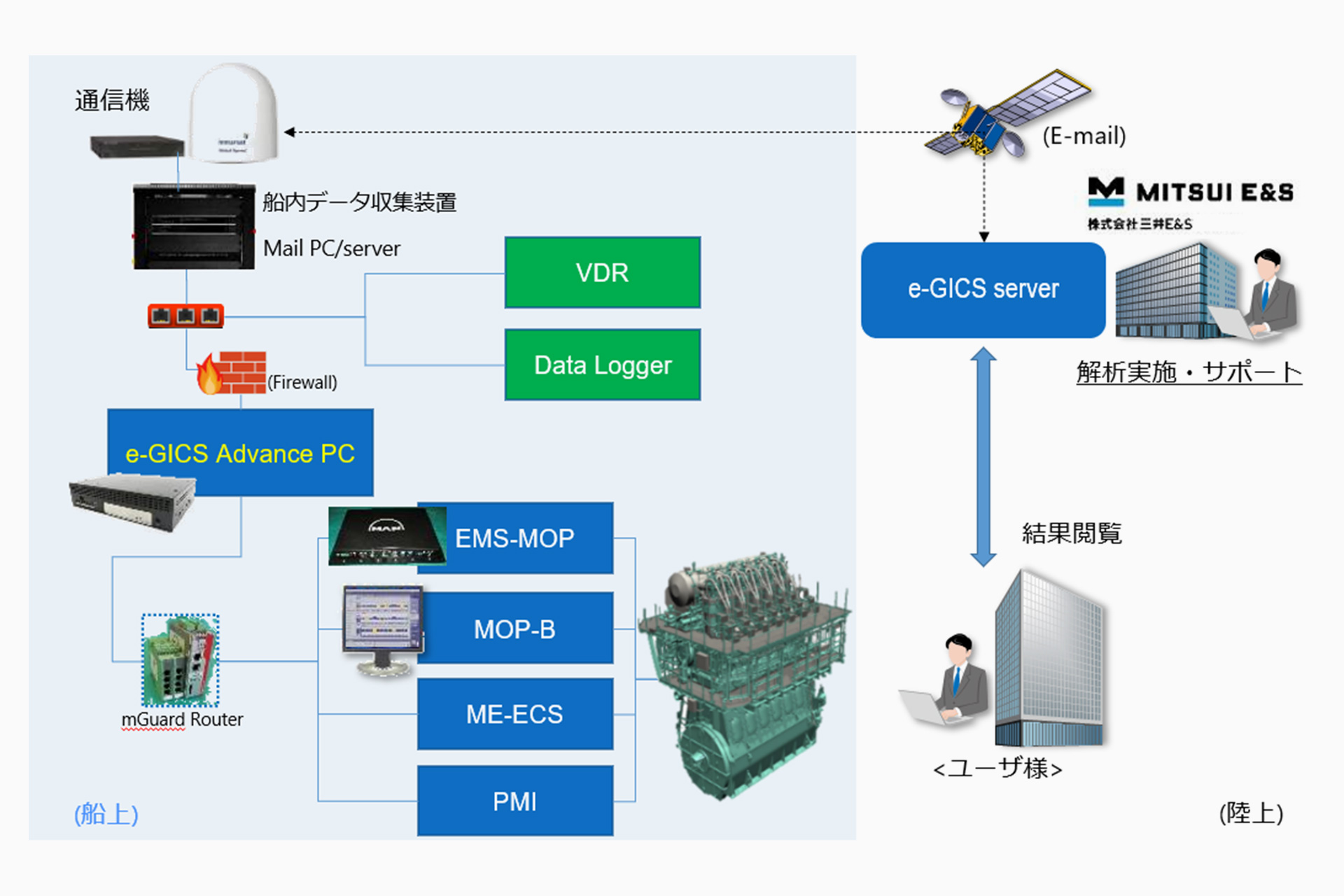

Automatic Data Collection

A data collection PC will be installed in the vessel to collect the data from the VDR, Data Logger and Main Engine. The data is periodically sent to our e-GICS database, and performance analysis is automatically carried out. This system will save time for the crew as all the process from data input to diagnosis are automated.

Additionally, it will be easy to discriminate the deviation from normal condition, and will find abnormality in early stages because of the high frequency of diagnosis of the system.

*Some data must be input manually (Fuel properties, Barometic Press., etc.).

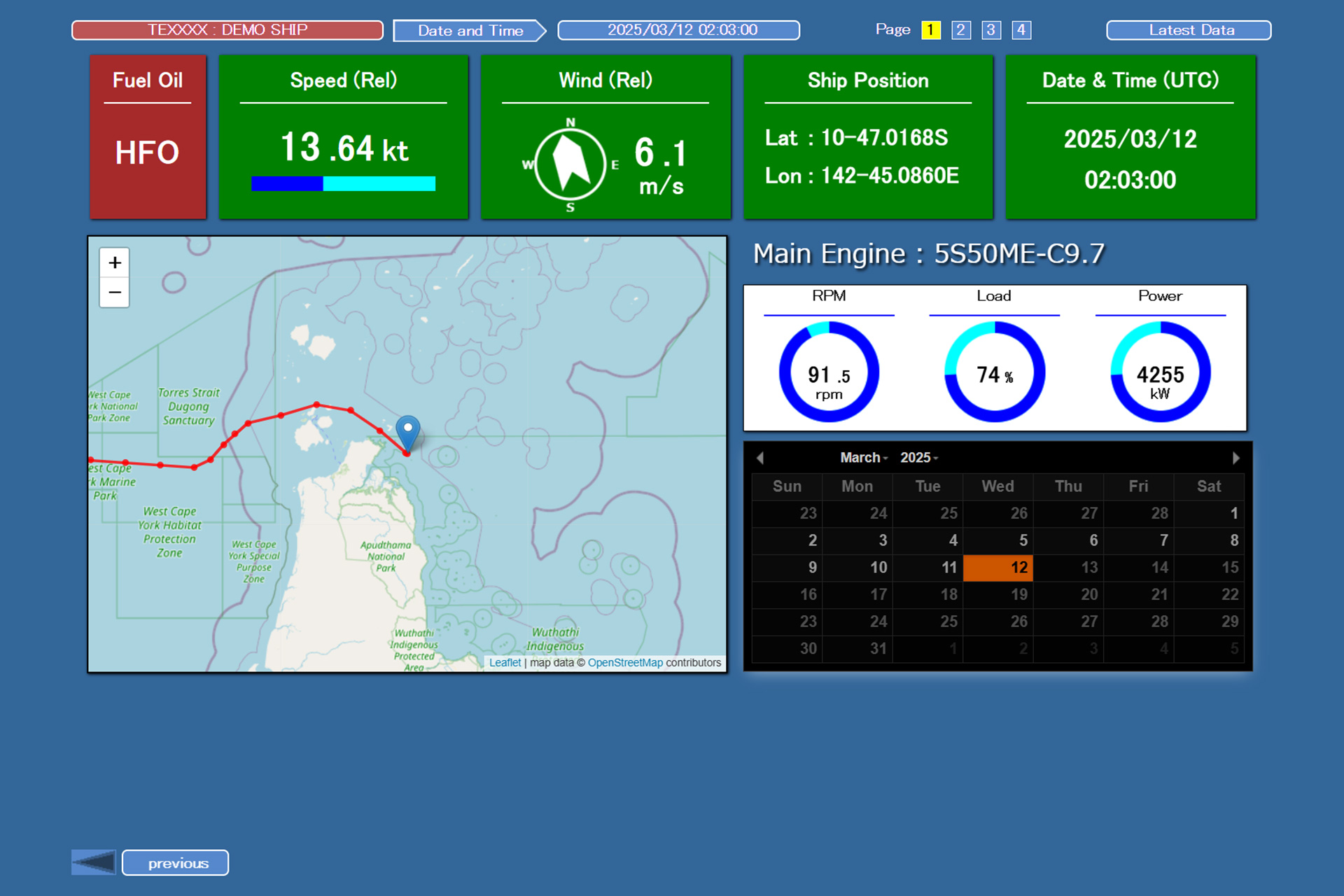

Dashboard

Key operational data, such as cylinder pressure and cylinder lubrication settings, is displayed on the dashboard. It is also possible to display trend charts of selected data.

AI anomaly detection (located on land)

Our proprietary AI anomaly detection engine MADOCS (Mitsui Abnormal Detecting system for On-site Collected Sensor data), which is deployed on shore, performs accurate anomaly detection through machine learning by utilizing big data that combines sensor data with meteorological and oceanographic data.

Condition diagnosis (performance diagnosis + combustion diagnosis + AI abnormality detection)

Detailed performance and combustion diagnostics are triggered by AI abnormality detection results to comprehensively diagnose the condition of the main engine. Combustion diagnosis is carried out using in-cylinder pressure waveform data automatically collected from PMI Auto tuning, and can determine not only abnormalities in the combustion process but also the combustibility of the fuel, thereby minimizing fuel-related problems.

Delivery Records

- Installed: 46vessels

- Scheduled: 69vessels

(As of February, 2025)

Catalog

Contact

Inquiries about products

Technoservice Center, Marine Propulsion Systems Div.