CMAXS LC-A

Monitoring of main and auxiliary engines and services aimed at improving preventive maintenance rates.

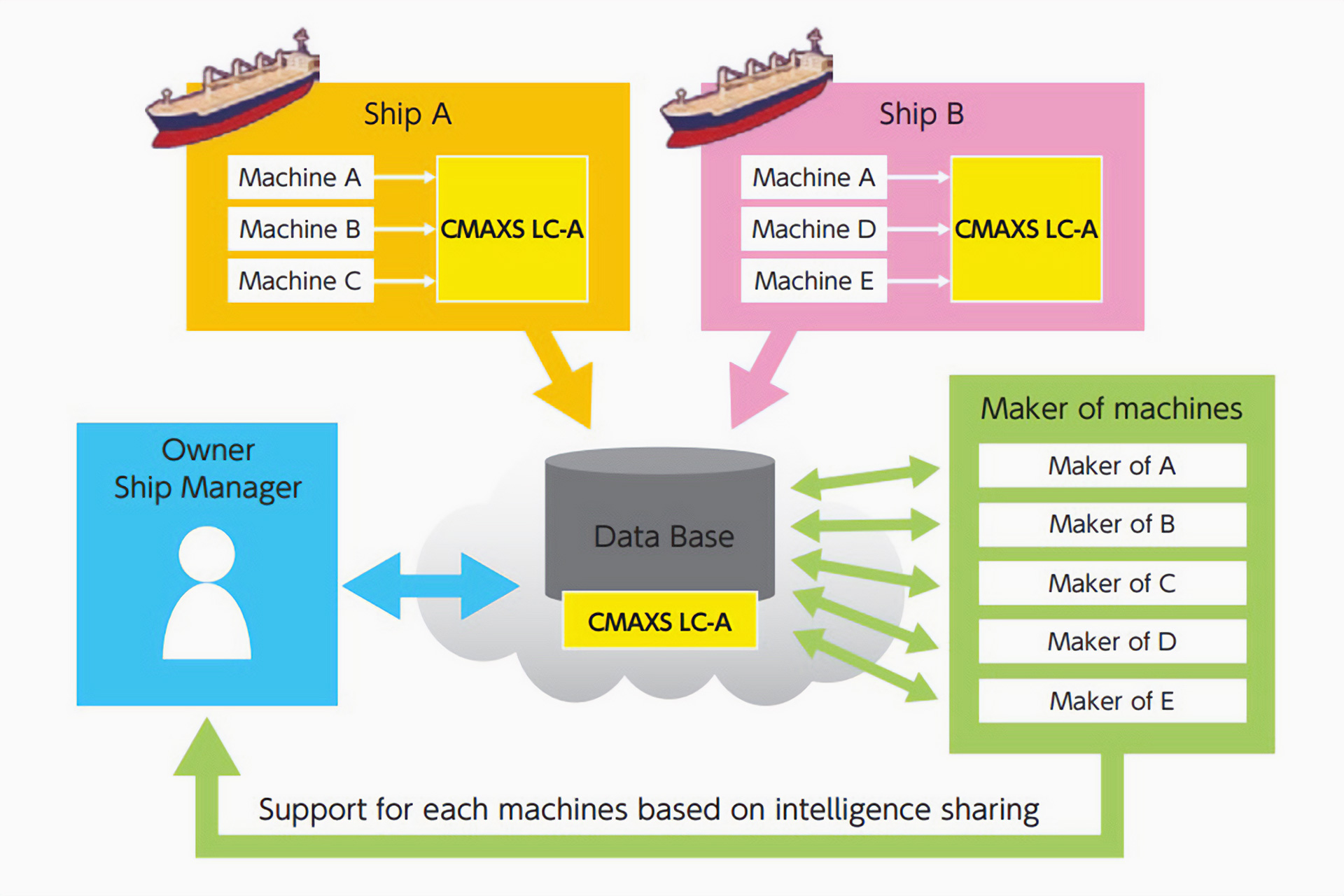

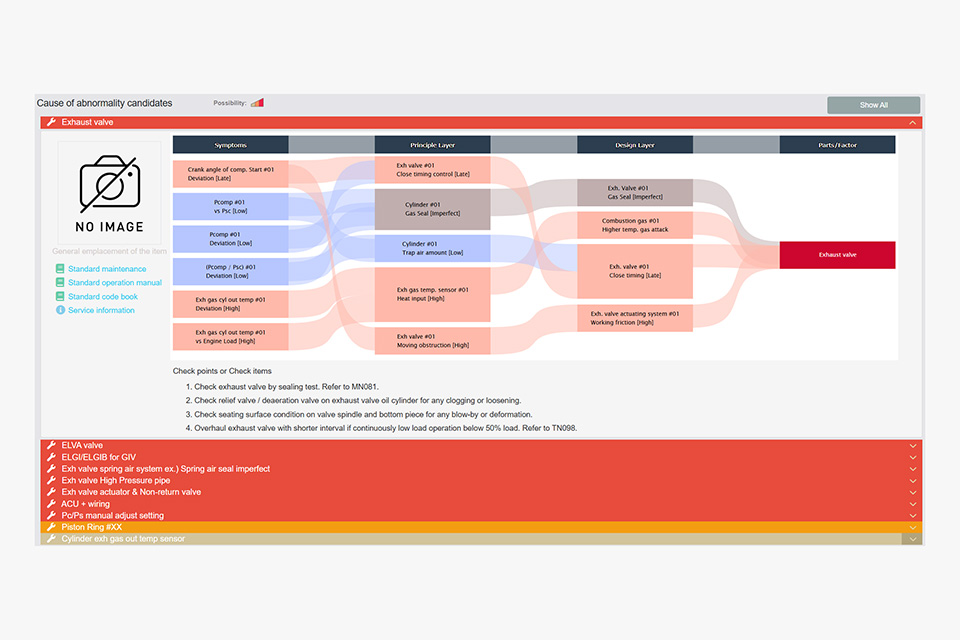

CMAXS LC-A* is an integrated platform, developed in collaboration with equipment manufacturers, and is capable of centralized diagnosis and support for all engine room equipment. In addition to automatic anomaly diagnosis and automatic condition diagnosis, it is equipped with troubleshooting functions that automatically provide inspection and recovery work instructions when abnormalities occur, as well as maintenance management information, providing great value.

*Joint development with PrimeTech Consulting Service (formerly ClassNK Consulting Service)

PrimeTech Consulting Service Co., Ltd.

Main Features

- Diagnose and support any type of device.

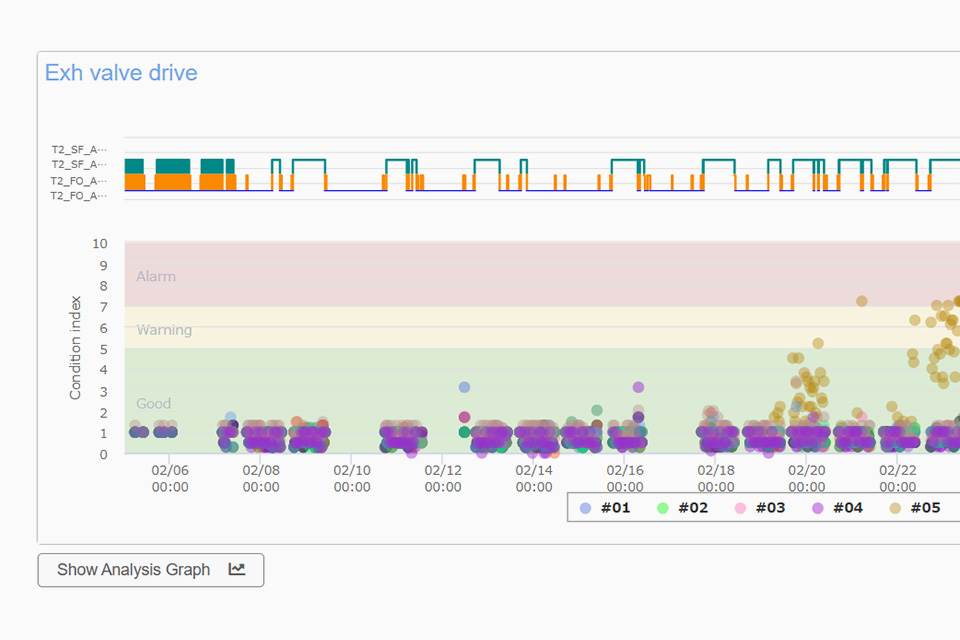

- An onboard self-contained system with automatic diagnosis enables early detection of abnormalities and correction of deterioration, maximizing the lifespan of equipment.

- Operational costs can be reduced by optimizing operation settings according to conditions.

- Maintenance management is also possible, including adjustment of maintenance work plans, history management, and document management of maintenance work reports and consumables lists.

- Centralized management of equipment information in the CMAXS Database enables information sharing between the ship, shipowner, ship management company, and equipment manufacturer.

Catalog

Contact

Inquiries about products

Technoservice Center, Marine Propulsion Systems Div.