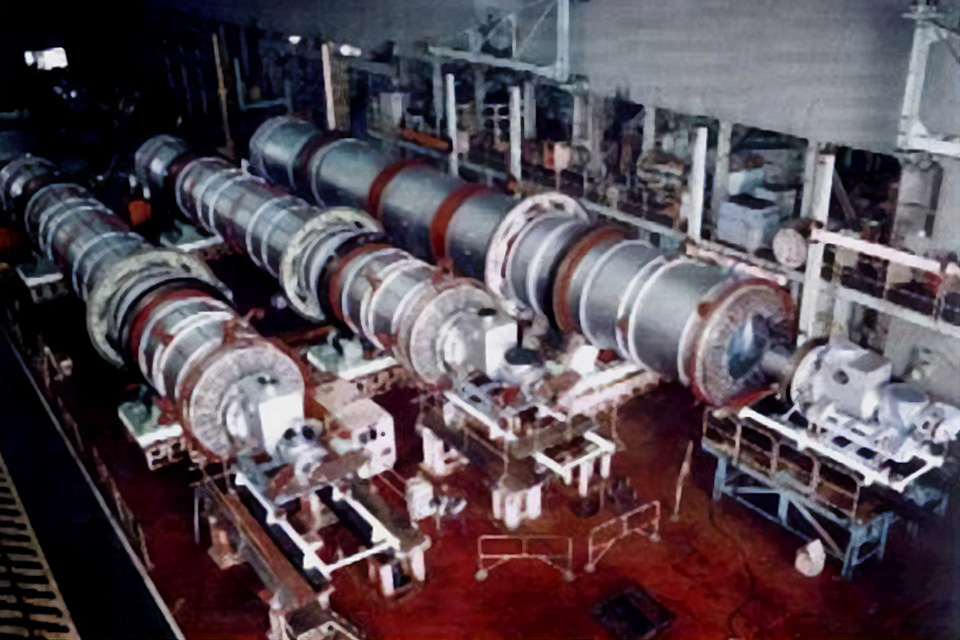

Steam Tube Dryer (STD)

Indirect heat rotating dryer using steam tubes heated by steam as heat source disposed inside the rotating shell.

Steam Tube Dryer (STD) is an indirect heat dryer using steam tubes heated by steam as heat source disposed inside the rotating shell. Steam is introduced into a header through a rotary joint and then distributed into the tubes. The header is also provided with condensate ejection pipes which discharge condensate as quickly as formed. The material to be dried is fed into a screw feeder through a chute and then into the STD. The material is then in contact with the steam tubes during passage through the STD and finally discharged from a discharge head.

Carrier gas accompanied by vaporized moisture travels in the STD, finally being removed from the STD.

Main Features

- STD provides higher thermal efficiency than any other type of dryer.

- Less flow of carrier gas compared with other types of dryers contributes to the reduction of material entrainment.

- Drying temperature can easily be adjusted by controlling steam pressure, thereby providing favorable conditions for heat-sensitive materials.

- STD is capable of processing larger capacity of material continuously.

- Compact gas sealing construction minimizes gas leakage from the dryer.

- Stable operation, high thermal efficiency, less flow of carrier gas and easy maintenance lead to low operation cost.

Achievements

MITSUI E&S has numerous achievements in equipment delivery. Please inquire about the equipment you need.

Contact

Inquiries about products

Sales Dept., New Business Development Div.

Inquiries about after-sales service

Sales Dept., New Business Development Div. (Tamano)