- Home

- News & Information

- MITSUI E&S Receives Contract for Development of Technology Supporting Linkage of Remote Automation RTG and On-Premises Chassis

Sep 28,2023

MITSUI E&S Receives Contract for Development of Technology Supporting Linkage of Remote Automation RTG and On-Premises Chassis

MITSUI E&S Co., Ltd.(President: Takeyuki Takahashi; Head Office: Chuo-ku, Tokyo; hereinafter "MITSUI E&S") has been selected following its application to participate in the FY2023 Port Technology Development Program for the development of technology enabling cooperation between Rubber-Tired Gantry (RTG1) cranes and on-premises chassis.2

MITSUI E&S has recently been officially commissioned by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) to participate in the FY2023 Port Technology Development Program and it has started the development of technology for linking auto/remote RTG (ARTG) and on-premises chassis inside port terminals.

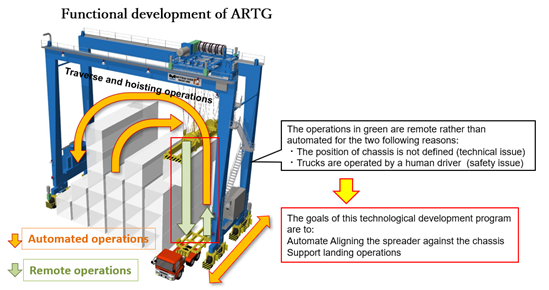

MITSUI E&S has already developed and is selling ARTG to improve productivity and work environments. To further improve the operability of its ARTG, MITSUI E&S will develop a support function that enables automated alignment of the spreader with the on-premises chassis as well as enabling semi-automated landing on the on-premises chassis. By doing this, MITSUI E&S aims to reduce the workload of ARTG operators and on-premises truck drivers and increase the efficiency of cargo handling.

MITSUI E&S plans to study and develop the system, conduct demonstration tests at our Oita factory, and establish the system by the end of FY2024.

Outline of the technology development project

The technical development project, MITSUI E&S plans to develop the following functions:

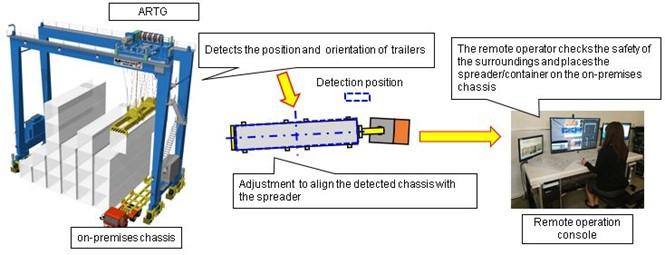

1. Detection of the position of on-premises chassis

2. Communication of position adjustment instructions from RTG to on-premises trucks

3. Automatic adjustment of the position of spreader

After adjusting the spreader's position using the above functions, the system is completed with semi-automatic landing of the container/spreader under the supervision of a remote RTG operator.

Future Development Plans

1. FY2023:

Develop the system for detecting containers/chassis under RTG

Develop the system for automatically transmitting movement instructions to on-premises truck

2.FY2024:

Develop the system for detecting containers/chassis under RTG

Conduct demonstration tests using RTG owned by the MITSUI E&S Oita factory for development purposes.

Optimize functions and establish the system

1. Rubber Tired Gantry (RTG) crane: A crane that has legs with tires on both ends which requires no rails on the ground.

2. On-premises chassis: A chassis used exclusively within container terminals to transport containers between quay cranes and container yards.

The information contained in the articles is current at the time of publication.

Products, service fees, service content and specifications, contact information, and other details are subject to change without notice.

Contact