- Home

- Business & Products

- Marine Propulsion System

Marine Propulsion System

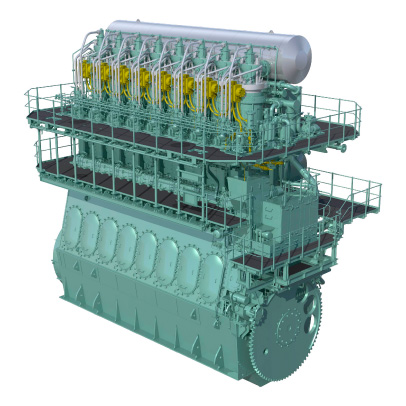

We play a key role in ships. Our mission is the continued evolution of global marine logistics and transport. While ensuring reliable quality, we will leverage environmental technologies, IoT and big data to become a one-stop propulsion system supplier supporting optimized operations. With our marine engines +α, we will contribute to realization of a low-carbon recycling society and to progress in the digitalization of marine logistics.

FACT

-

- Since the production of our first diesel engine in 1928, we have created a history of performance lasting more than 90 years.

-

- The cumulative total horsepower of the Marine engines produced under a single brand reached 119 million in FY2023.

-

- We have the largest share of the Japanese market. We are far ahead of the competition in production volume.※Figures include Mitsui E&S DU Co., Ltd. and Makita Corporation that is sublicensee

VALUE 1

A track record of supporting

global marine logistics and transport

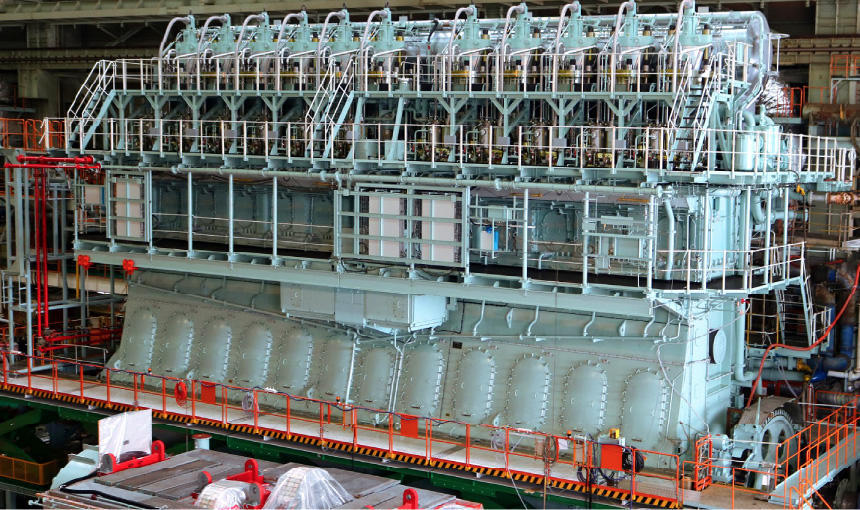

Since 1926, when we signed a technical alliance with Burmeister & Wain A/S (B&W), currently known as MAN Energy Solutions, we have been producing a single engine model. In FY2023, the cumulative total number of horsepower of these engines reached 119 million. The total number of engines produced has surpassed 7,000. Our accumulated achievements and experience as a world-leading marine engine manufacturer have enabled us to earn the trust of our customers.

VALUE 2

Environmental technologies enabling

the creation of a sustainable future

We accumulate a wide variety of technologies that reduce nitrogen oxide (NOx), sulfur oxide (SOx) and greenhouse gas (GHG) emissions, such as dual fuel engines, exhaust gas recirculation and waste heat recovery. We provide engines and peripherals, including those developed independently, that perform up to the standards of environmental regulations, to help conserve the global environment and develop sustainable marine logistics and transport.

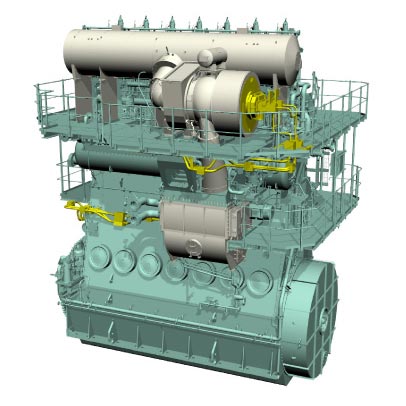

- THS2(Turbo Hydraulic System type2)

- waste heat recovery system -

THS2 utilizes the excess exhaust gas energy from the highly efficient turbocharger and recovers it as hydraulic power.The power can be used to drive the engine rotation and reduce fuel consumption rate by up to 2%.Thus, the Energy Efficiency Design Index (EEDI) can be improved. In addition, when operating at reduced speeds, THS2 supports the rotation of the turbocharger with hydraulic power from the crankshaft.

- Dual fuel engines

-

Fuel conversion is the key to low-carbon and decarbonization of ships.To fulfill our responsibility as a leading manufacturer of marine engines, we were the first in the world to develop an LNG-fired engine in 1994. We have orders for more than 35 marine engines fueled by LNG, methanol, LPG, etc. as of 2023. Futhermore we are also developing next-generation fuel marine engines such as ammonia and hydrogen. In the future, we can contribute to Net-Zero Emissions by using green fuels produced from renewable energy sources or CO2.

VALUE 3

Preventive maintenance leveraging IoT,

M2M and big data

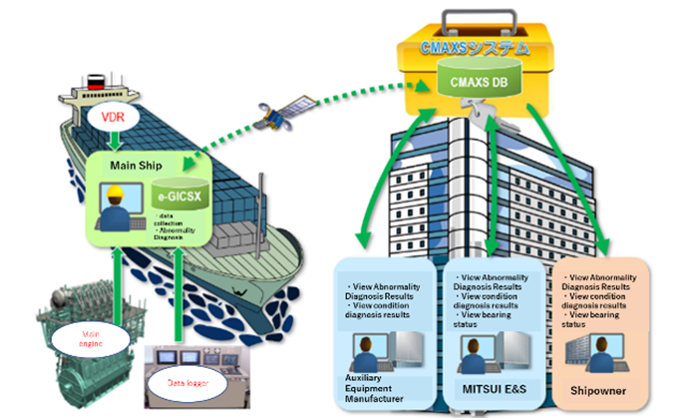

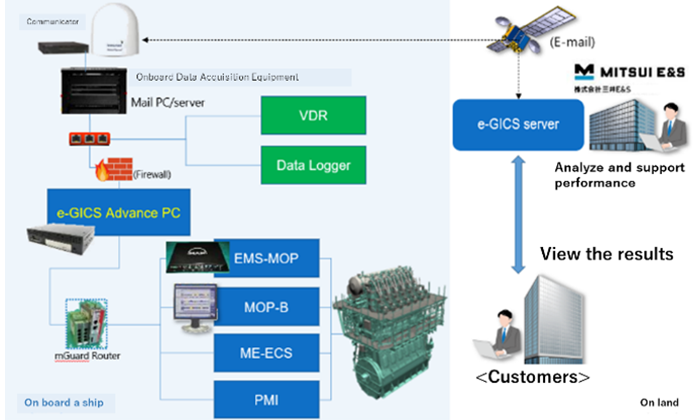

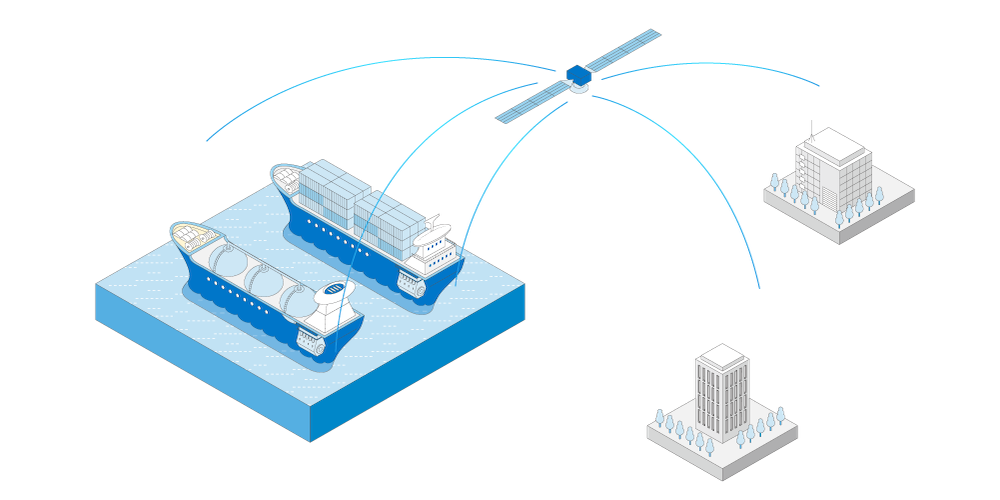

Preventive maintenance made possible by the early detection of abnormalities in engines supports optimized, safe ship operations. Together with Nippon Kaiji Kyokai (ClassNK), we have jointly researched and developed the CMAXS e-GICSX system incorporating IoT, M2M, big data analysis and other technologies to enable the remote monitoring of main engines and the detection of abnormalities. In addition, we have independently developed e-GICS Advance to help reduce the workload bourn by crew members and life cycle costs.

Maintenance

instructions

from land

Operations based on

maintenance instructions

from land

Automated ship operations

VALUE 4

After-sales service bases around the world

To keep engines in the best condition after delivery and help users make the most of them, we have three after-sales service bases in Japan and five outside Japan to quickly respond to needs for inspections, maintenance, troubleshooting and technical consulting services.