- Home

- Business & Products

- After-sales Services

- After-sales Service for Gas Turbine Co-generation Sytem

After-sales Service for Gas Turbine Co-generation SytemBusiness & Products

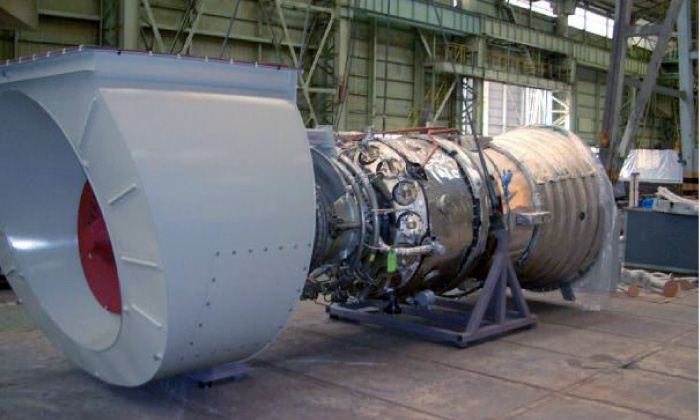

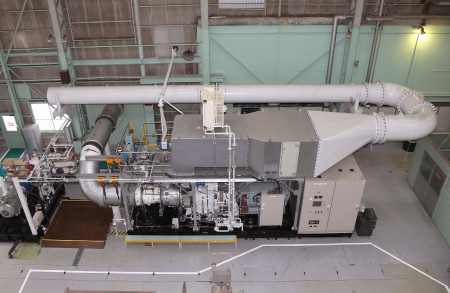

Mitsui E&S gas turbines range from 1 to 24 MW of generating output as gas turbine co-generation units and widely applied such as in food, chemical, semiconductor industries and also district heating and chilling, and have the following features:

Features

- High efficiency and low cost

- Simple system configuration

- Environmentally-friendly, a high total efficiency and less NOx & CO2 emissions

- Application to a variety of purposes, from hospitals, office buildings, etc., to industrial use such as factories.

- A variety of burning fuels, such as town gas, LPG, kerosene, heavy fuel and byproduct oil

Lineup of products

We provide after-sales services to the following Mitsui E&S gas turbine co-generation systems.

| Type | Outline | Survey |

|---|---|---|

| MSC40 ~ MSC130 |

Simple co-generation systems using gas turbines produced by U.S.-based Solar Turbines Inc. in the Mitsui Solar Co-generation (MSC) Series of seven packages ranging from 4 MW to 13 MW |  |

| MACS60 ~ MACS130 |

Variable heat and power co-generation systems using gas turbines produced by U.S.-based Solar Turbines Inc. in the Mitsui Advanced Co-Generation System (MACS) Series of five different packages ranging from 7 MW to 17 MW |  |

| SB15 ~ SB120 |

Simple cogeneration systems based on the SB15 to SB120 Series of independently developed gas turbines. Four different packages from 3 MW to 24 MW have been delivered to customers. |  |

| GP1000 MPP1000 SB5-COPRA GP1000-RECSS SB5N |

Co-generation systems based on the independently developed SB5 1 MW gas turbine. The SB5-COPRA variable heat and power model and the GP1000-RECSS regeneration cycle model have been delivered to customers. The enhanced efficiency SB5N model was recently added to the lineup. |  |

Service

- Stable parts and spare engine supply

- A complete supply process including design, manufacturing, quality control, procurement system and stock control management has been established to supply necessary parts in a timely manner.

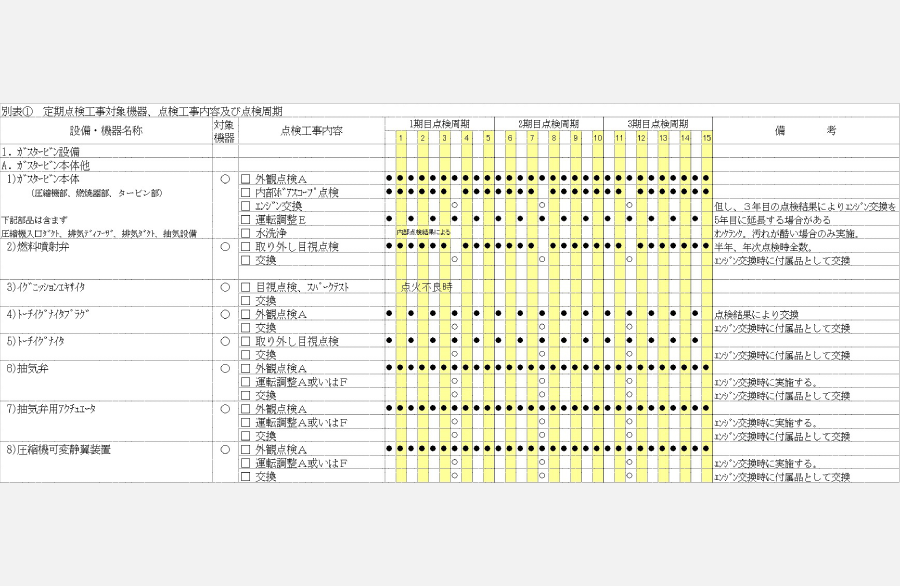

- Long-term comprehensive maintenance contract

- A budget plan for customers' maintenance cost and facility maintenance management is made easy by leveling out the long-term routine inspection costs as a yearly base.

-

- Technical service for emergencies

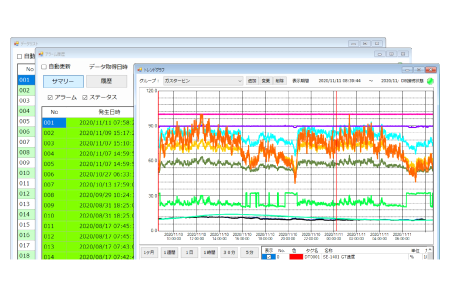

- We respond to customer's expectations with preventive maintenance by tendency management utilizing the complete online support system at Tamano office and emergency response service at abnormal · trouble occurrence. In addition, Tamano and Chibaʼs technical staff at each sales office are developing swift service.

- Improvement of facility function and performance

- Our proposals for functional and performance improvements based on customers' needs and technology development makes the customers' facility more valuable and helps to improve their business management efficiency.

- Technical support

- We hold technical training sessions to provide customers with support for their facility operations. These sessions tailored to the specific customers' facility and wishes have been praised by many customers.

- New Business Development

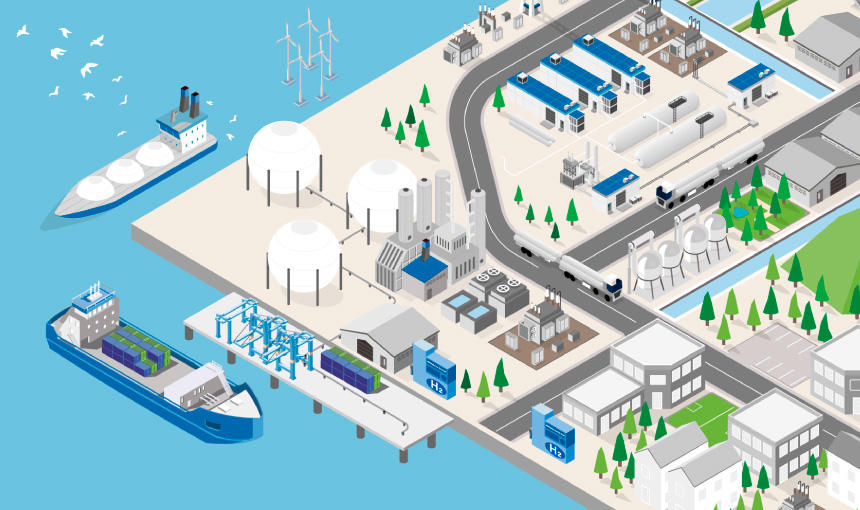

- Decarbonization business

- Industrial Machinery

- After-sales Services

- CREWS

- FALCONs

- Drone Snap

- Radar Business

- Hydraulic model testing equipment

- Docking system for aircraft maintenance

- Marine Propulsion System

- Logistics & Systems