MRVBusiness & Products

- MRV is designed to fulfill all possible requirements from end user.

-

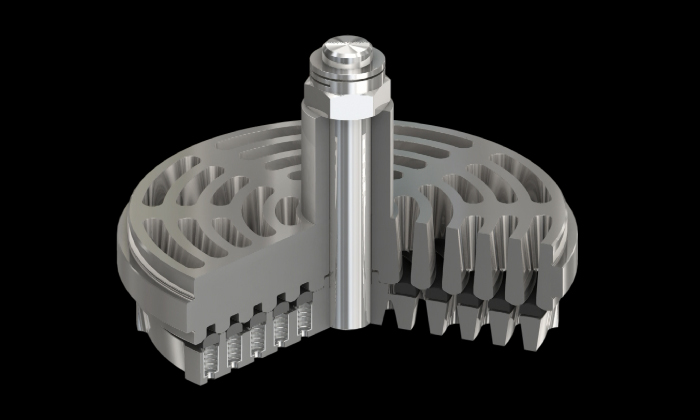

MRV is a ring type valve.

Enhanced aerodynamic performance such as the streamlined valve ring and highest efficient flow pass leads to dramatic energy saving.

Also, optimal design, based on Valve Dynamic Analysis, maximizes valve efficiency to each compressor.

In addition, robust and durable valve parts enables our customer to cut down maintenance cost. Even to the compressor which is in usage of severe environment, such as equipment which uses gas containing liquid and sludge. MRV acquires anti-stiction design, which prevents valve ring and spring from facing typical damage caused by stiction brought by such conditions.

Main Features

-

- Mitsui E&S will promise sustainable development to provide the best solution for our customer's need.

-

- MRV is the best choice for reciprocating compressor.

- Mitsui's new compressor valve, called MRV, is the best choice for reciprocating compressor. Reciprocating compressors require highest reliability and efficiency, and MRV is developed from the view of a compressor builder who knows all about optimization of actual compressors.

-

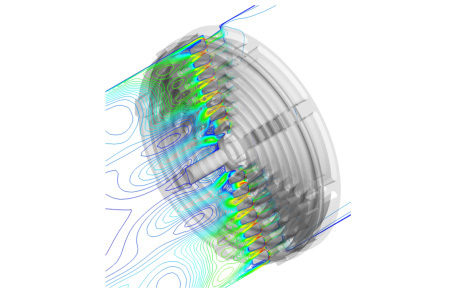

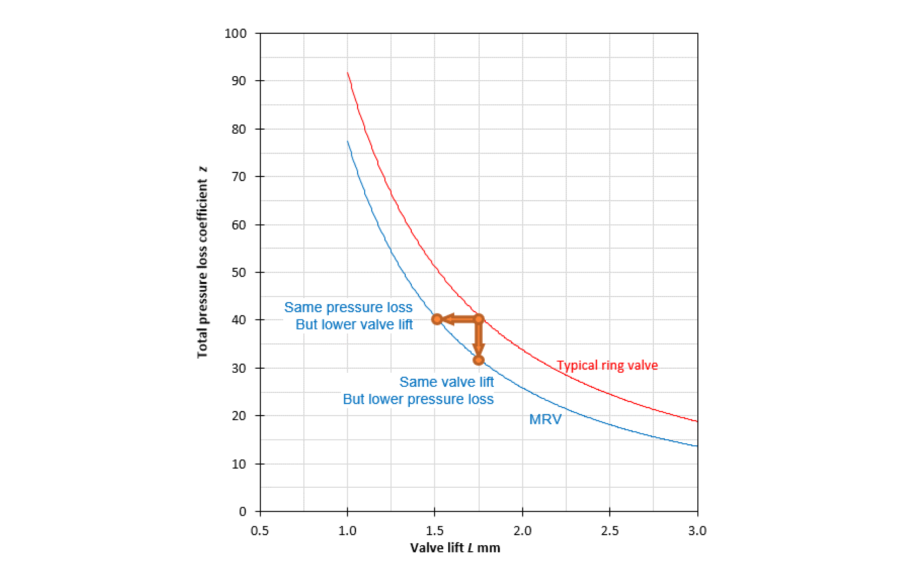

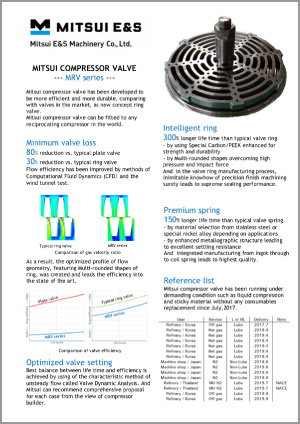

- Minimizing valve loss

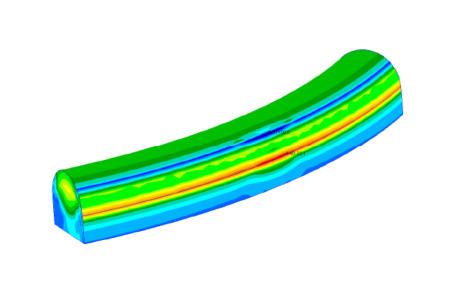

- We achieved a design of the most flow efficient valve of any typical ring type valve on the market today, by using testing methods such as Computational Fluid Dynamics (CFD) and the wind tunnel test. This latest design has an optimized profile of flow geometry. It features Multi-rounded shapes of each ring, which creates the efficiency. As an indicator of valve efficiency, MRV achieved a drag reduction coefficiency up to 80% when compared against typical plate type valves and a 30% reduction when compared against typical ring type valves.

-

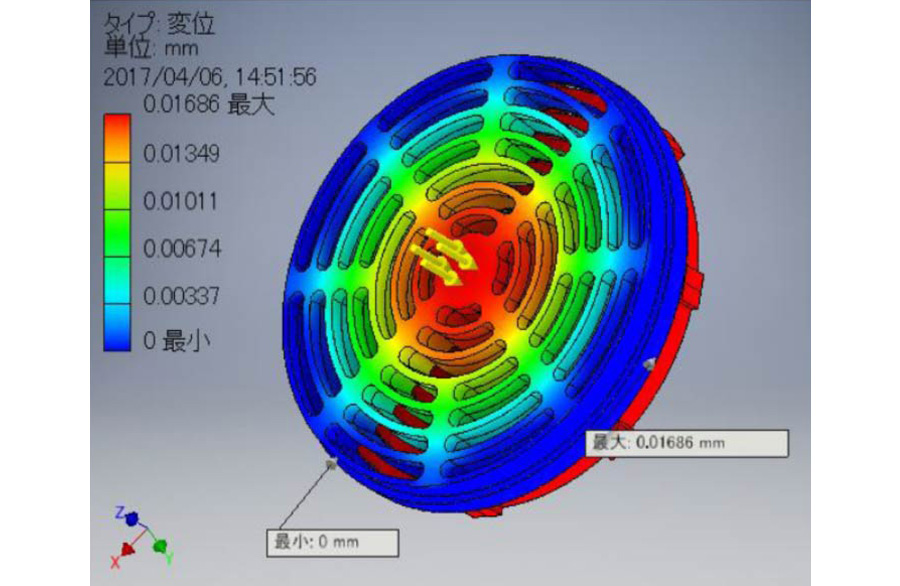

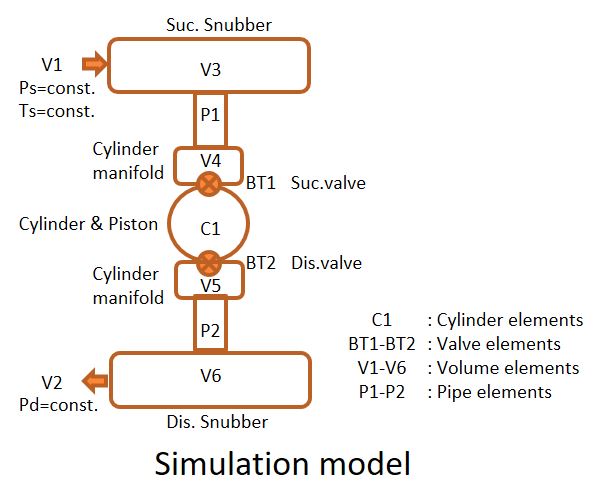

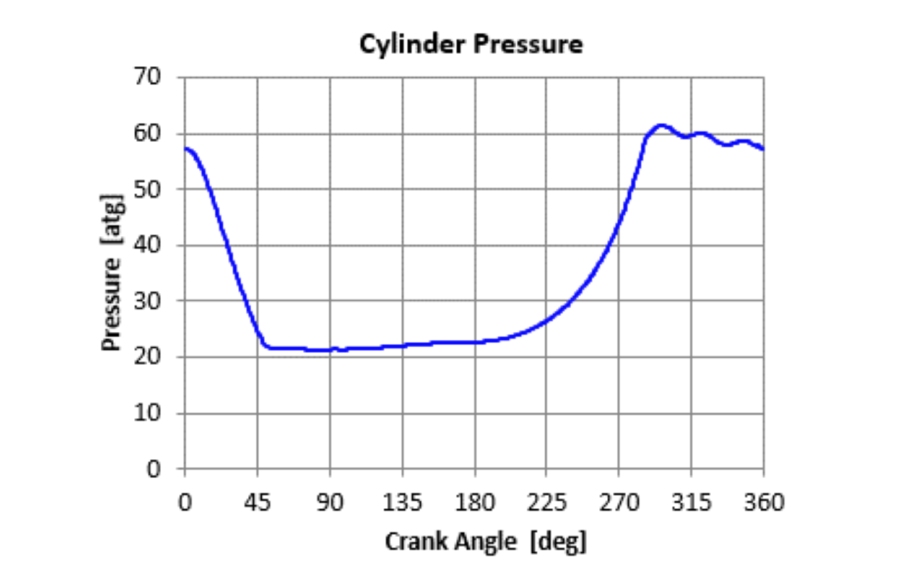

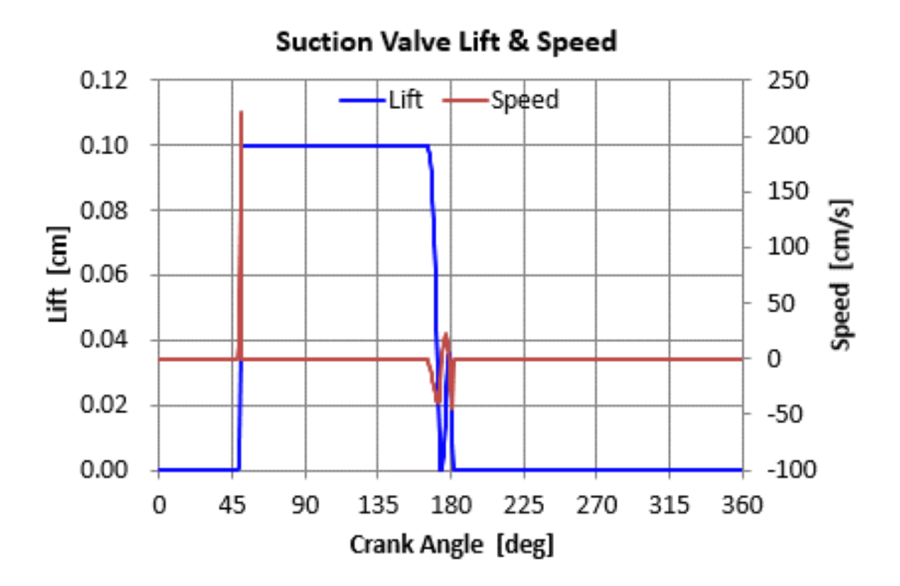

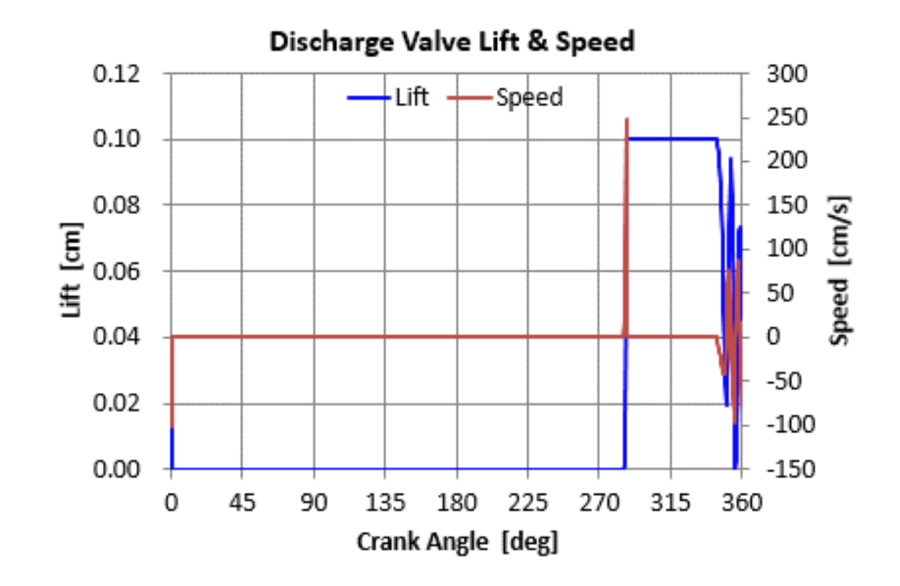

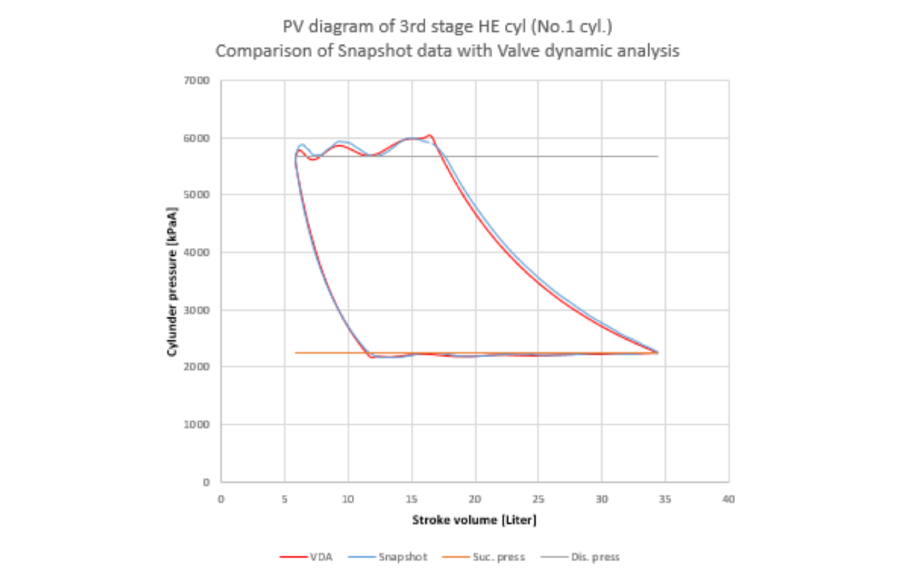

- Valve Dynamic Analysis

- We developed an original simulation program of Valve Dynamic Analysis by use of the characteristic method of unsteady flow. The simulation model includes not only simple compressor data but also snubber data, so that effects on valve motion caused by gas pulsation, can be evaluated. In addition, our program can also simulate valve stiction conditions caused by lubricant or sludge, and show how valves are damaged. Mitsui valve dynamic analysis is the most practical approach to simulate an actual operating compressor. As a result, the best balance between life time and efficiency can be calculated for each compressor. Also, we can recommend a comprehensive proposal for each case as a compressor builder.

-

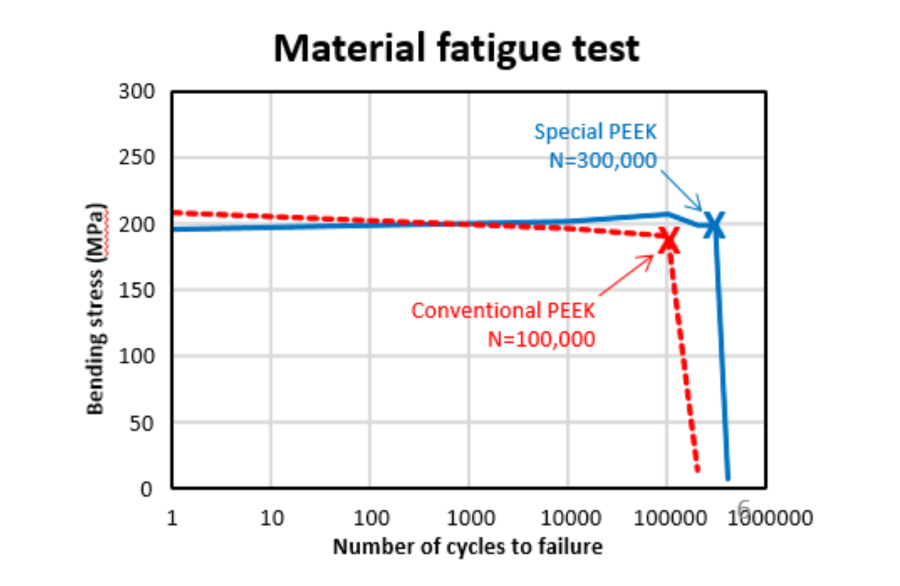

- Intelligent ring

- Ring material is Special Carbon/PEEK, which is enhanced material for strength and durability. The life time of the ring is 300% longer than typical valve type ring.

Multi-rounded shapes will enable the valve to overcome high pressure and impact force.

In addition, this ring is designed with inimitable knowhow, and precise machining of the ring which leads to supreme sealing performance.

-

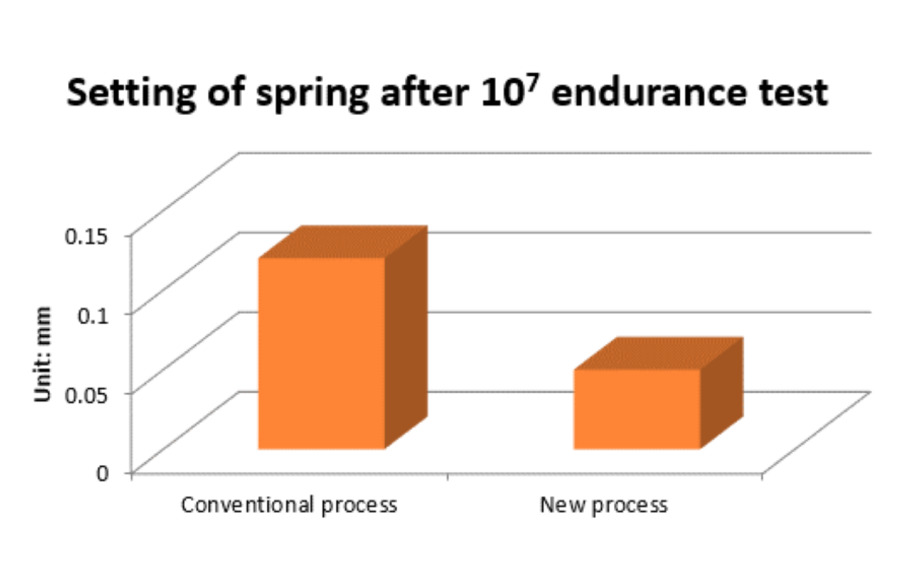

- Premium spring

- Spring material is selected from stainless steel or special nickel alloy depending on its applications. The Premium spring's life time is 150% longer than a typical valve spring. Integrated manufacturing from ingot through to coil spring leads to the highest quality. In addition, enhanced metallographic structure is applied by a new manufacturing process and excellent performance has been proved by various examination.

-

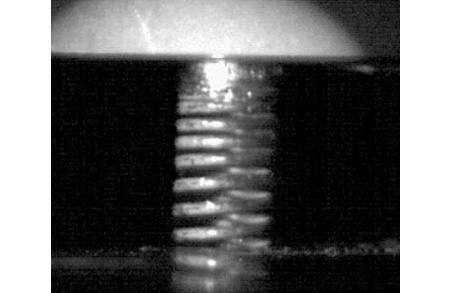

- Verification test by in-house compressor

- When evaluation of new production and improvement, they are verified from various view points by installing them into In-house compressor. By making use of experience and knowhow as a compressor builder, Mitsui will deliver compressor valves with highest reliability and quality.

Delivery Records

-

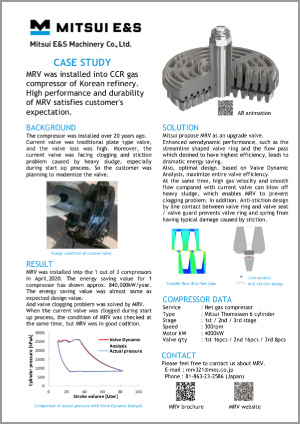

- Net gas compressor

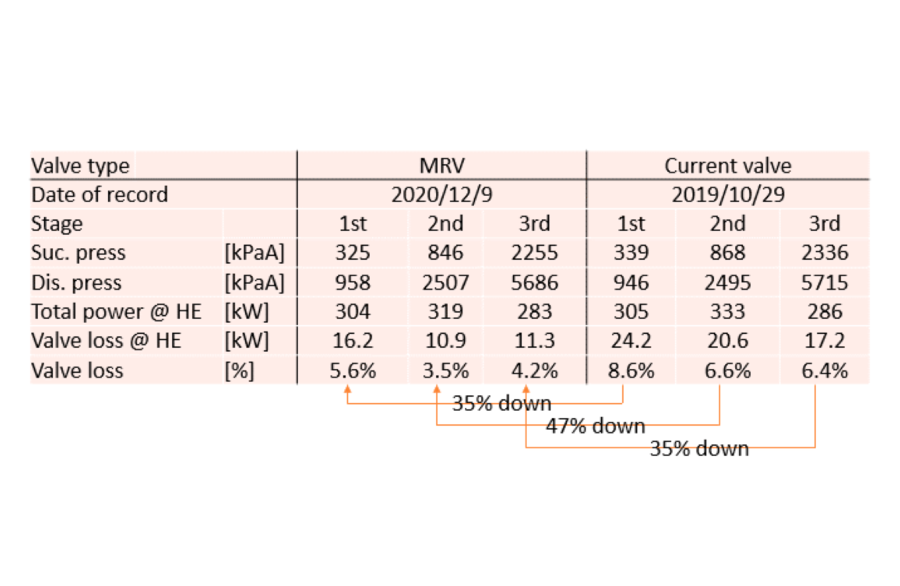

- MRV was installed into the net gas compressor in April, 2020. The energy saving value has been approx. 840,000kWh/year after MRV installation. Therefore the high efficiency of MRV has been proven. In addition, before MRV installation, the current valve was facing clogging caused by heavy sludge, especially during start up process. However, the problem was solved after installation of MRV.

-

- Crude tower off gas compressor

- MRV was installed to the crude tower off gas compressor in July, 2017. It was only installed to discharge side. Valve internal parts were in good condition after 3.5 years operation under heavy demand conditions. Therefore robustness and durability of MRV has been proven. In addition, energy saving value was approx. 22,400kWh/year.

Inquiries about products

- Contact

- Marketing Dept.

New Business Development Div.

- TEL

- +81-863-23-2586

- FAX

- +81-863-23-2348

- mrv321@mes.co.jp

Inquiries about after-sales service

- Contact

- Marketing Dept.

New Business Development Div.

- TEL

- +81-863-23-2586

- FAX

- +81-863-23-2348

Catalog

- New Business Development

- Decarbonization business

- Industrial Machinery

- After-sales Services

- CREWS

- FALCONs

- Drone Snap

- Radar Business

- Hydraulic model testing equipment

- Docking system for aircraft maintenance

- Marine Propulsion System

- Logistics & Systems