- Home

- Business & Products

- Robotics

- Manipulator

ManipulatorBusiness & Products

-

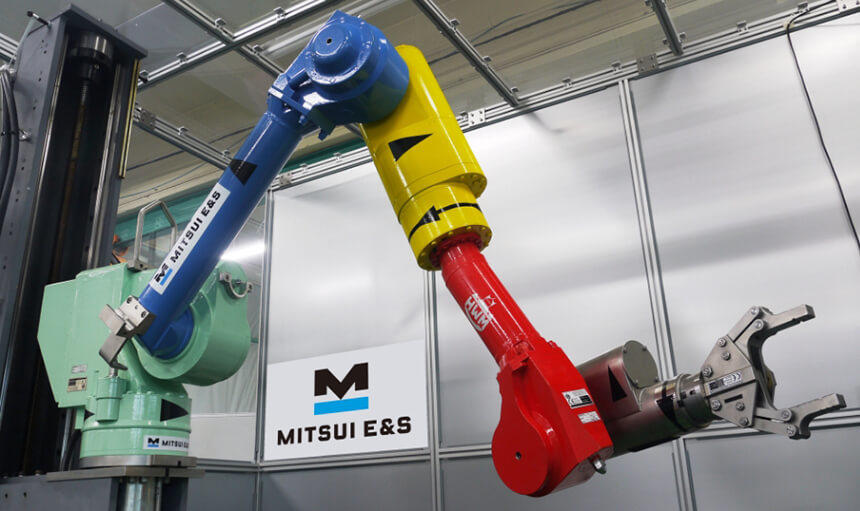

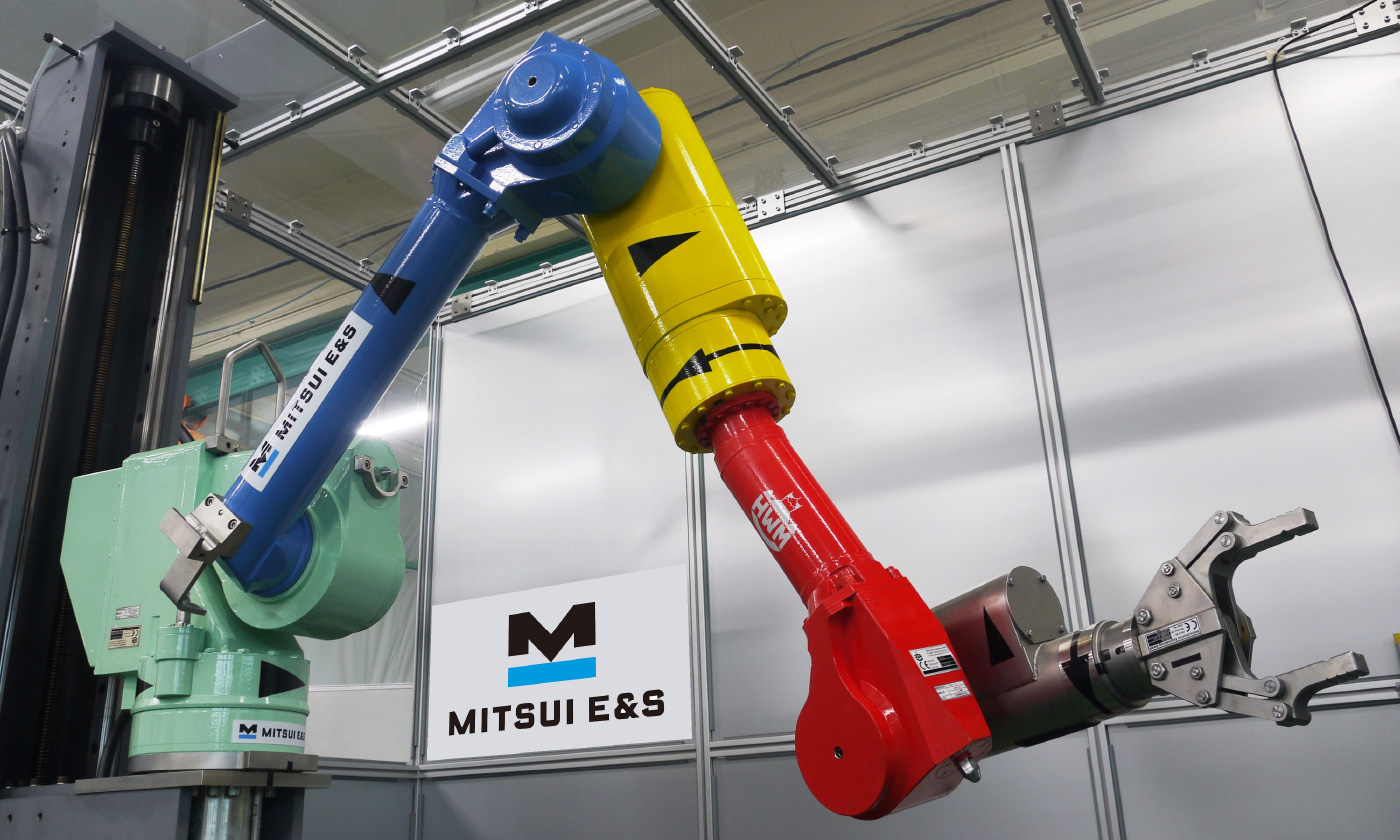

High Radiation Tolerance Power Manipulator A1000SL

- 30 years since we provided robots and manipulators for extreme work sites.

We will solve various problems in work areas where no way humans could enter. -

Since we Mitsui E&S entered into a business alliance with Walischmiller Engineering GmbH (Germany) in 1993, which has a worldwide reputation for robots and manipulators for nuclear facilities, we have delivered 11 robots and about 300 manipulators in Japan.

After the Great East Japan Earthquake in 2011, decommissioning of nuclear power plants in Japan has accelerated, and 24 out of 57 plants are under decommissioning or have been decided to be decommissioned. (As of November 2022)

In place of humans, robot manipulators can be used under extreme conditions where it is not easy for humans to enter, and through it we will solve social problems. -

Manipulators Supply Record for Japanese customers (as of November. 2022)

-

A100/A110 Master Slave Manipulator(MSM)265 sets

-

A201/A202 Master Slave Manipulator(MSM)28 sets

-

A1000 Power Manipulator / Servo Manipulator11 sets

-

Main Features

We have successfully developed the world's first sensor-less control technology for decommissioning work, which eliminates position control sensors in the arm, and have developed a sensor-less robot with more than twice radiation tolerance (total dose of 2MGy) as compared with conventional one.

Delivery Records

-

A1000SL-Handling Load 200kg

A robot for decommissioning work that adopts sensor-less control technology. A1000SL has achieved reduction of wire by no position sensor and high radiation tolerance of 2MGy, which is the highest level in Japan, and also can be used underwater. -

A1000-Handling load 500kg

A1000 has the longest history of any electromechanical power manipulator supplied by HWM, with delivered 120 units worldwide. It can handle a variety of loads from 100kg to 500kg, and is suitable for heavy duty work. -

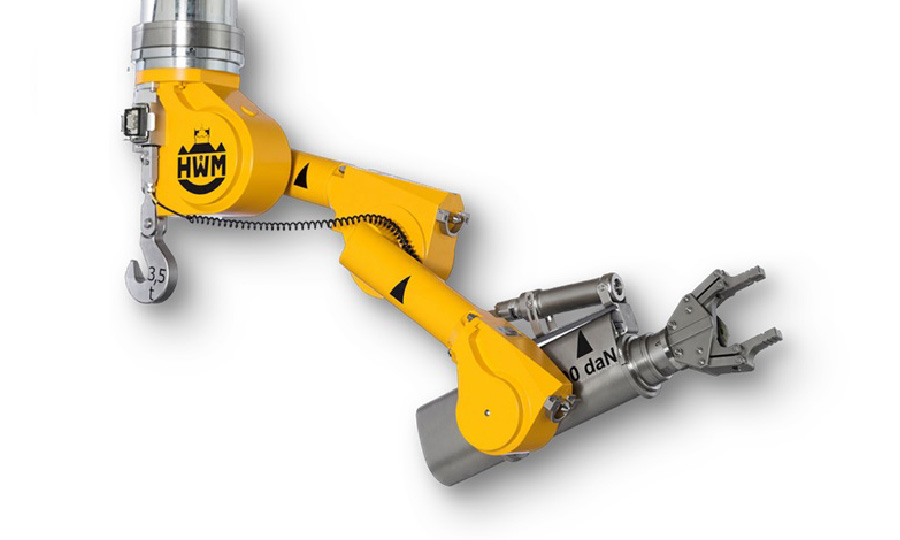

TELBOT

TELBOT incorporates all motors in a drive block at the base of the arm and uses torque tubes and bevel gears to transmit power, enabling infinite rotation of all axes. It can be applied to tasks that require finesse in a little place, with delivered 58 units worldwide. -

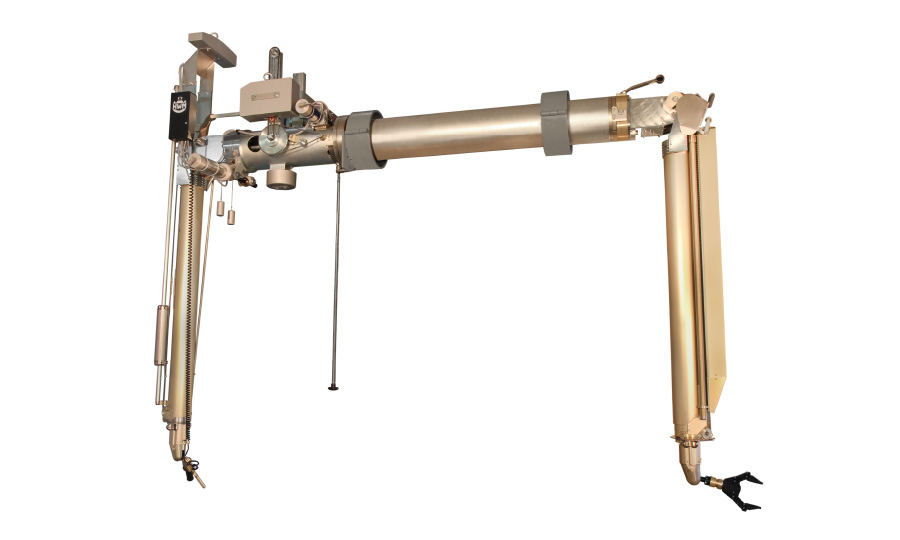

A100

A100 Master Slave Manipulator (MSM) consists of three-part structures with a through-wall tube connecting the master arm on the operator's side and a slave arm that is installed in the cell. The arm can be operated back and forth, left and right, and up and down, and has the ability to expand and contract. MSM manufactured by HWM has been highly acclaimed by users as being easy to use with its low operating resistance compared to other companies' products, and has been delivered to about 300 nuclear power related facilities in Japan.

Inquiries about products & after-sales service

- Contact

- Growth Business Promotion Marketing Dept.

Growth Business Promotion Div.

MITSUI E&S Co., Ltd.

- TEL

- +81-3-3544-3951

- FAX

- +81-3-3544-3055

- New Business Development

- Decarbonization business

- Industrial Machinery

- Mechatronics & Special Construction

- After-sales Services

- CREWS

- Marine Propulsion System

- Logistics & Systems

- Portainer®(Quayside Container Crane)

- Transtainer®(Transfer Crane in Container Yard)

- CTMS

- Crane Inspection by DroneSnap(Automatic Flying Drone)

- Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive Maintenance

- Drone Snap: flight file creation application for equipment inspection/patrol