- Home

- Business & Products

- Robotics

- Manipulator Demonstration Room

Manipulator Demonstration RoomBusiness & Products

-

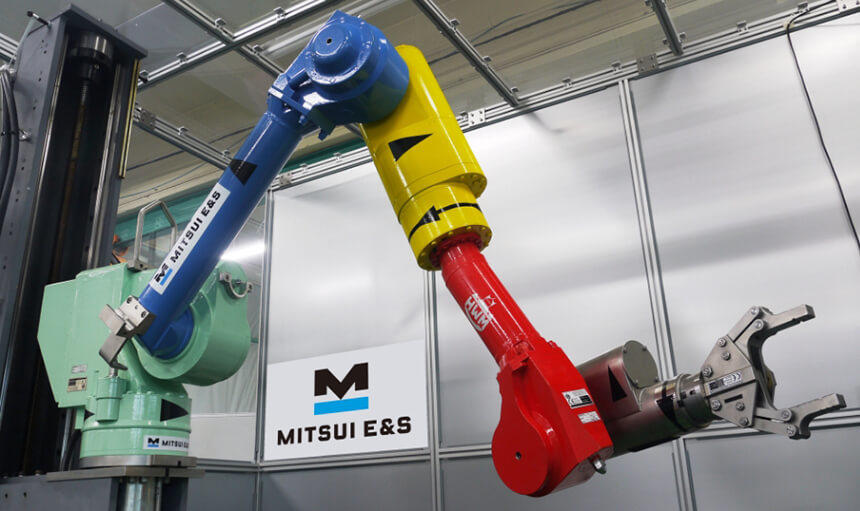

Manipulator Demonstration Room

- Opened a dedicated facility for remote handling system to provide education, training, and technical verification in accordance with the diverse requirements of customers.

- We have supplied remote handling system such as robots and manipulators mainly to the nuclear fuel cycle field. With the progress of decommissioning project of the Fukushima Daiichi Nuclear Power Plant and other nuclear-related facilities, the need for demonstration, technical verification and training of remote handling system has been grown. In response to such request, we opened a demonstration room at our Tamano-works in Okayama Prefecture in July 2019.

Main Features

The demonstration room consists of an exhibition and technology verification area of about 200 square meters, an education and training area for operation & maintenance of about 130 square meters, and a conference room of about 60 square meters.

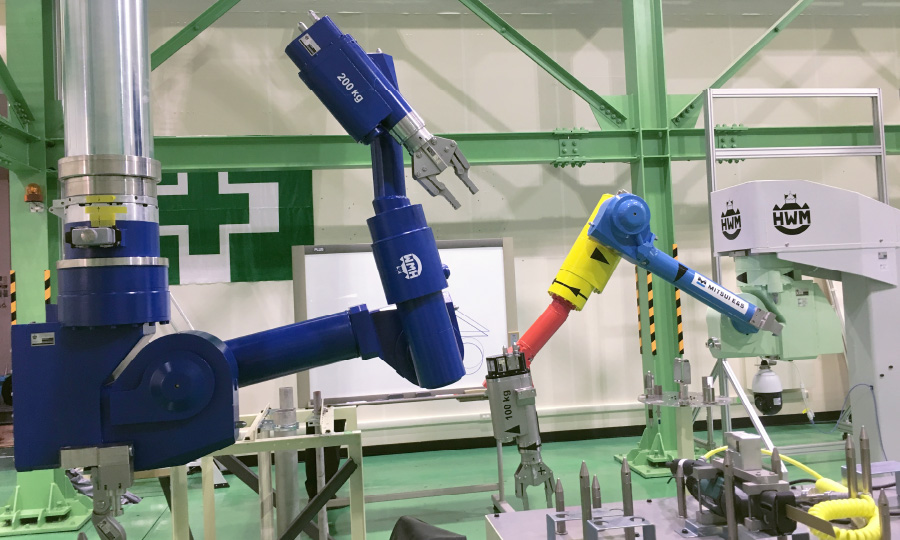

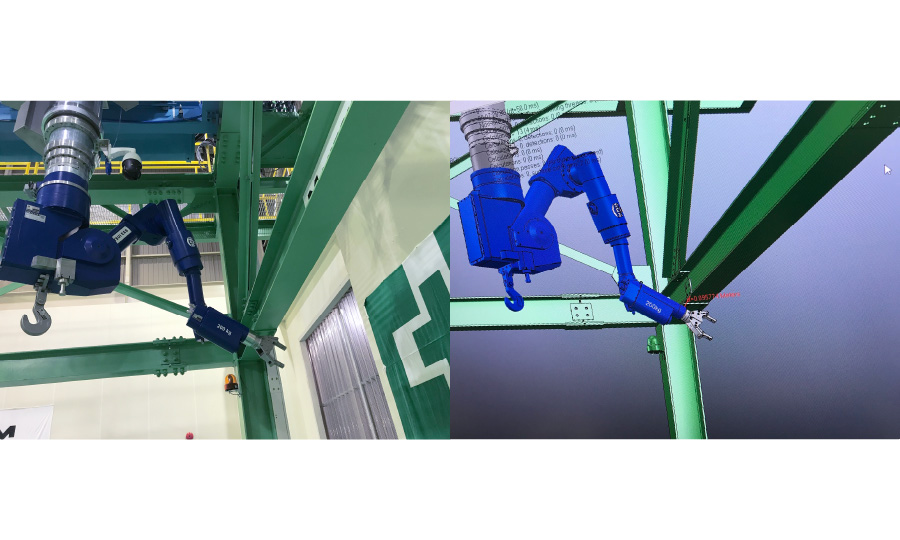

In the area, we have two Power Manipulators (A1000SL series) for decommissioning work (200 kg type with crane and 100 kg types) adopting sensor-less control technology, four mechanical manipulators types and overhead traveling crane (2.8t).

We have launched solution businesses that meet the diverse needs of our customers such as education / training (operation & maintenance) and technical verification by mockups.

Delivery Records

-

Exterior of Manipulator Demonstration Room

Manipulator Demonstration Room was opened in July 2019 in Tamano-works, and as of December 2020, more than 250 customers from 20 companies have visited the room. -

Technical verification

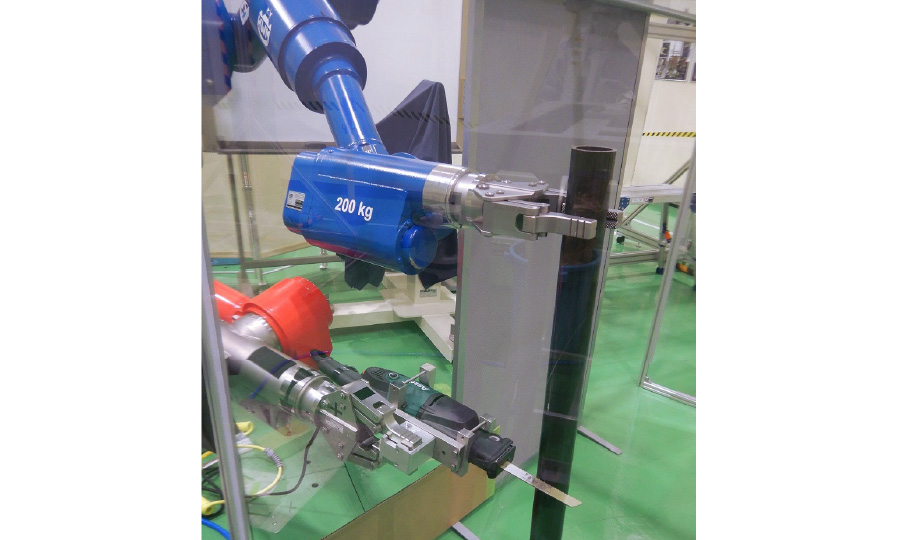

We provide a place for preliminary simulations and technical verifications using actual machines to verify various issues for customers, and propose the most suitable remote handling system.

In addition to technical validation, such as workability and accessibility studies, we can also support with proposal for suitable operation modes and teaching functions, operational support, and camera operation in remote operations. -

-

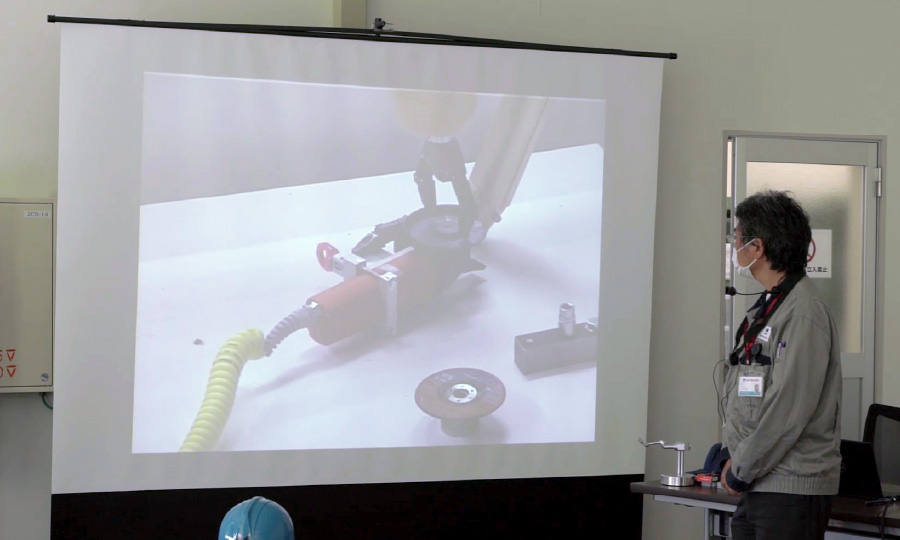

Education / Training (operation & maintenance)

We provide education and training in operation, maintenance, troubleshooting, etc. using actual machines.

By training in an environment that simulates a remote control room, we have feedback from customers that it's easy to understand what remote operation with cameras and simulators, etc. -

-

Conference room

Manipulator Demonstration Room is equipped with a conference room directly connected to the exhibition and technical verification area, where the results of technical verification, education and training can be discussed in a timely manner while touching the actual machine.

Inquiries about products & after-sales service

- Contact

- Growth Business Promotion Marketing Dept.

Growth Business Promotion Div.

MITSUI E&S Co., Ltd.

- TEL

- +81-3-3544-3951

- FAX

- +81-3-3544-3055

- New Business Development

- Decarbonization business

- Industrial Machinery

- Mechatronics & Special Construction

- After-sales Services

- CREWS

- Marine Propulsion System

- Logistics & Systems

- Portainer®(Quayside Container Crane)

- Transtainer®(Transfer Crane in Container Yard)

- CTMS

- Crane Inspection by DroneSnap(Automatic Flying Drone)

- Next-generation Crane Advance Remote Monitoring System (CARMS) and Advanced Preventive Maintenance

- Drone Snap: flight file creation application for equipment inspection/patrol